Yes, Boeing’s CEO is a qualified engineer, but that’s NOT ENOUGH

In a well-craft 945 word section of Jon Hemmerdinger’s article on Boeing’s recovery, the quotes include the word “SAFETY” ONCE.[1]The body of the report, 475 words, IS focused on the company’s financial health.

Those who contributed to this report are recognized as technical influencers on aviation stocks. Their words send messages to shareholders and the investment world. The gravamen of their commentary can fairly be characterized as emphasis on production, supply chains’ reliability and sales. Those are legitimate points of their insights. But their tilting towards those measures can actually incentivize stupid shareholders-first behavior.

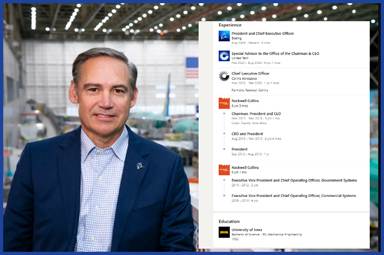

Yes, it is important to have ENGINEERS on Boeing’s Board and senior management. Mr. Ortberg has that essential credential, but so too did Mr. Muilenburg, see FN 2 below. His resume had impressive academic and work experience. Clearly that was not what was missing in Seattle or Chicago or Washington!!!

What the several blue chip review boards that examined Boeing’s MAX 8 performance found was a virtual ABSENCE of Safety Management Systems’ adoption, attention and advocacy. Increasing the aircraft production rate CANNOT BE AT THE EXPENSE OF SAFETY.

To provide honest forecasts of Boeing’s future, these cognoscenti MUST incorporate a measure of safety progress of equivalent reliability as their earnings projections. AIRPLANES WITHOUT an FAA TYPE certificate are worthless; they cannot be sold or flown. Boeing is all too familiar with the suspension [2] of its Production Certificate.

Ortberg’s engineering focus shows signs of shifting Boeing

3 March 2025

On 20 February, Boeing chief executive Kelly Ortberg told investors and the company’s vast network of suppliers exactly what they wanted to hear.

“Supply chain on the 737 is in good shape… I feel like we are headed in the right direction,” he said during a Barclays investor conference. “We don’t have any supply chain constraints that are going to keep us from ramping up to 38 per month.”

Observers might be forgiven for taking those comments with heavy skepticism, however. After all, Boeing’s leadership have a well-documented history in recent years of glossing over troubling and unresolved issues with optimistic assurances, only for them to later prove more troubling and less resolved than implied.

REAL ASSURANCES

But this time might be different, since the man making the assurances had no hand in creating the troubles in the first place. It was not[3] former CEO Dennis Muilenburg, who ran the company into and during the 737 Max grounding, nor his successor David Calhoun, a board-member turned CEO under whom Boeing’s recovery never gained traction.

A former outsider and one-time Collins Aerospace chief, Ortberg was hired by Boeing’s board last August to make something in the way of positive action finally happen for it.

Considering his reception so far, including from typically cautious industry analysts and consultants, Ortberg could be called the face of New Boeing.

KELLY ORTBERG has been praised for BRINGING AN ENGINEERING FOCUS BACK TO BOEING

“I’m very bullish on Boeing. I think Kelly is going to turn this company around. Supply chain is improving,” KEVIN MICHAELS, managing director of AeroDynamic Advisory, told Boeing suppliers during a conference near Seattle in February. “I am hopeful we are coming out of THIS STUPID SHAREHOLDERS-FIRST ERA that has punished this industry.”

“Boeing is really instilling a SENSE OF QUALITY AND SAFETY-FIRST to their supply chain now,” says MICHAEL APLIN, consulting leader at aerospace and defence advisory Patriot Industrial Partners. There is a sense that under Ortberg Boeing is “shifting back toward an engineering and quality company”.

“My confidence stems from Kelly Ortberg’s strong engineering background and PRESENCE ON THE SHOP FLOOR at Boeing’s manufacturing sites surrounding Seattle. Contacts there have expressed unanimous optimism post-strike,” Aplin adds.

But there is no doubt that Boeing has a long, long way to go.

The company has lost significant competitive ground to Airbus. Areas of its supply chain remain wobbly. Financial pressures abound. And Boeing faces the incredibly complex task of completing its planned acquisition of supplier Spirit AeroSystems.

FINANCIAL RESULTS

On the financial front, Boeing closed 2024 with a $3.9 billion fourth-quarter loss (the first full quarter on Ortberg’s watch), bringing its full-year 2024 loss to a staggering $11.8 billion. The results reflected all sorts of problems, but most impactful were a production slowdown prompted by the January 2024 inflight blow-out of a 737 Max 9’s mid-cabin door-plug, and a late-year, nearly three-month stoppage in the Pacific Northwest due to a machinists union strike.

Those factors left Boeing able to deliver only 348 commercial jets last year, down one-third from the 528 aircraft it delivered in 2023. By contrast, Airbus delivered 766 aircraft in 2024.

Boeing has also lagged in the orders department. The company signed deals last year covering the purchase of 569 jets – reduced to 377 net orders when accounting for cancellations. By comparison, Airbus took net orders for 826.

Boeing ended January with 5,554 jets in its backlog, including 4,296 737s, 109 767s, 427 777s and 722 787s. Airbus, meanwhile, has nearly 8,700 jets in its backlog, reflecting the competitive challenges facing the US manufacturer.

But analysts see reasons for optimism, starting at the top.

“I would argue still that Dave Calhoun was perhaps the worst CEO… of any company ever created,”[4] Richard Aboulafia, also with AeroDynamic, said in February. “Kelly Ortberg, by contrast, I think is a pretty darn good guy. I like what I’m hearing out of Boeing… I’m kind of a believer in their recovery plan.”

The company is also on firmer financial footing after raising $24 billion in fresh capital late last year.

Against that backdrop, Ortberg says the airframer is on track to SIGNIFICANTLY HIKE 737 MAX PRODUCTION, and hence deliveries, this year – a critical step toward ensuring more cash is soon moving through its front door.

The US Federal Aviation Administration (FAA) capped 737 production at 38 jets monthly last year following the door-plug blow-out, which occurred because WORKERS FAILED TO INSTALL SECURING BOLTS DURING PRODUCTION.[5]

Boeing has not recently been producing close to 38 737s monthly. But Ortberg has said it intends to accelerate output, hitting the rate-38 cap this year before boosting output, with FAA approval, to 42 narrowbodies monthly.

The company will need to complete a “capstone review” with the regulator to demonstrate its readiness before the FAA approves a rate exceeding 38 monthly, the CEO has said.

Boeing this year also aims to hike 787 production to seven from five jets monthly, and to deliver 75-80 of those widebodies, up from 51 last year. But Ortberg notes that the 787 programme remains hindered by supply shortages – including of heat exchangers reportedly supplied by Collins Aerospace – and hold-ups to certification of cabin seats.

The company has also made recent progress winnowing its once-massive inventory of undelivered 737 Max and 787s, and is preparing to shutter so-called “shadow factories” – the sites where it has been completing rework to fix defects prior to delivery.

At the end of 2024, Boeing’s undelivered inventory included 55 737 Max 8s and 25 787s produced prior to 2023, down from respective figures of 140 and 50 787s at the end of 2023, Boeing chief financial officer Brian West says….

[1] The phrase THIS STUPID SHAREHOLDERS-FIRST ERA can be favorably read to say that $ was > SAFETY!!! Similarly, the statement— “WORKERS FAILED TO INSTALL SECURING BOLTS DURING PRODUCTION”, which also reflects safety concern.

[2] De Facto the Boeing PC was on hold.

[3] TO THE CONTRARY, Muilenburg, who held a bachelor’s degree in aerospace engineering from Iowa State University, followed by a master’s degree in aeronautics and astronautics from the University of Washington, was most responsible for Boeing’s FAILURES. As the company’s senior executive and leader off its board, appears to have overlooked the shoddy engineering that was attributable to these tragedies IN ORDER to beat AIRBUS in financial competition. Calhoun was never meant to be much more that a stopgap. There was plenty of engineering competence at the highest level. Under FAR Part 5, Muilenburg was THE ACCOUNTABLE EXECUTIVE for safety. “RES IPSA LOQUITUR.” [cite]

[4] See FN 1.

[5] Blaming the workers is simply myopic. There should have been appropriate work cards, sign-off by a line inspector, QA/QC procedures and final inspections. All of those positions and procedures are management responsibilities. Under SMS the Accountable Executive is responsible for oversight of these functions.