RTX’s response to GTF microscopic metal bits shows FOQA works around the world

Two reporters1 have written about RTX’s PW1100G Geared Turbofan Engines and the company’s determination that microscopic contaminants discovered in the powdered metal could expose the components to the risk of accumulating micro-cracks in advance of their specified service lives. The Popular Mechanics piece traces this remedial SAFETY ACTION reported by a Vietnamese airline about a DISC PROBLEM ON different powerplant produced by a joint venture. RTX should be commended for identifying this risk, but some measure of credit for this major risk diminution should go to FAA’s Flight Operational Quality Assurance and Flight Safety Foundation’s Global Safety Information Project (GSIP).

The lede of this event is that the Safety regime advocated by ICAO, adopted by the FAA (for some certificate holders and internally [?]), and most of the world’s CAAs IDENTIFIED AN INCIPIENT PROBLEM. The TC holder addressed it and is implementing an expensive resolution.

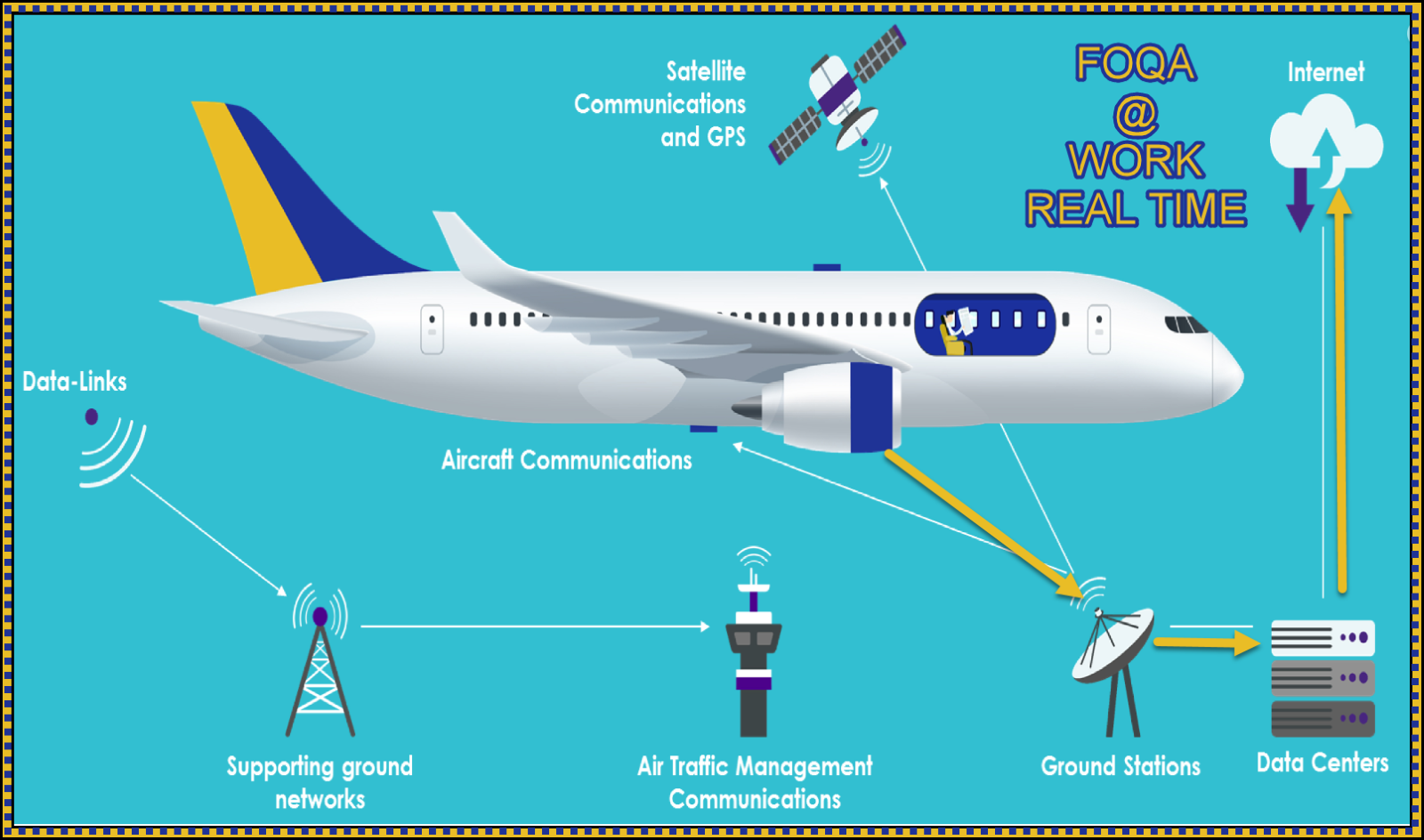

Global aviation safety has benefitted from learning from an enhanced database, statistical analyses, and preventative actions. This approach, designated Safety Management Systems (SMS), derives its virility from a meta computer which collects, collates, and curates inputs from

- Aviation Safety Action Program (ASAP)

- Aviation Safety Reporting System (ASRS)

- Flight Operational Quality Assurance (FOQA)

- 8900.1, Flight Standards Information Management System (FSIMS), Vol. 11, Chap.2, Sec. 2, Flight Operational Quality Assurance (FOQA) (PDF)

- FOQA Participants (PDF)

- Internal Evaluation Program (IEP)

- Line Operational Safety Audit (LOSA)

- Voluntary Disclosure Reporting Program (VDRP)

The power of these information resources grows exponentially as the number of participants grows. FAA’s list of certificate holders that subscribe to submitting safety data number over 50 as of 02/23/2021.

The FAA and other leading CAAs met and created Safety Management International Collaboration Group (SMICG). This network includes the Aviation Safety and Security Agency (AESA) of Spain, the National Civil Aviation Agency (ANAC) of Brazil, the Civil Aviation Authority of the Netherlands (CAA NL), the Civil Aviation Authority of New Zealand (CAA NZ), the Civil Aviation Authority of Singapore (CAAS), the Civil Aviation Safety Authority (CASA) of Australia, the Direction Générale de l’Aviation Civile (DGAC) in France, the Ente Nazionale per l’Aviazione Civile (ENAC) in Italy, the European Aviation Safety Agency (EASA), the Federal Office of Civil Aviation (FOCA) of Switzerland, the Finnish Transport Safety Agency (Trafi), the Irish Aviation Authority (IAA), Japan Civil Aviation Bureau (JCAB), the United States Federal Aviation Administration (FAA) Aviation Safety Organization, Transport Canada Civil Aviation (TCCA), and the Civil Aviation Authority of United Kingdom (UK CAA). Additionally, the Civil Aviation Department of Hong Kong (CAD HK), the International Civil Aviation Organization (ICAO), and the United Arab Emirates General Civil Aviation Authority (UAE GCAA) are observers to this group.

Another source of safety information is the Global Safety Information Project (GSIP) is a worldwide initiative led by Flight Safety Foundation that guides the aviation community’s response to challenges that may emerge from safety data collection and processing systems (SDCPS). Focus areas include safety data collection, safety data analysis, safety information protection, and safety information sharing. While GSIP initially concentrated on the Asia Pacific and Pan America regions, the project’s influence has steadily expanded to additional parts of the world.

CIVIL AVIATION AUTHORITIES, that have yet to implement a domestic FOQA or have not joined SMICG or GSIP, should consider enhancing their safety as well as contributing to the global airworthiness knowledge. We can help

RTX Must Fix Numerous Flawed Jet Engine Parts in Costly Recall

Ryan Beene

Bloomberg News

- FAA identifies more components made with faulty metal powder

- Engine recall to idle 650 Airbus jets in first half of 2024

Up to 1,200 Airbus Jet Engines Recalled

The recall was caused by on impurities in powdered metal.

BY SÉBASTIEN ROBLINPUBLISHED: JUL 27, 2023 10:11 AM EST

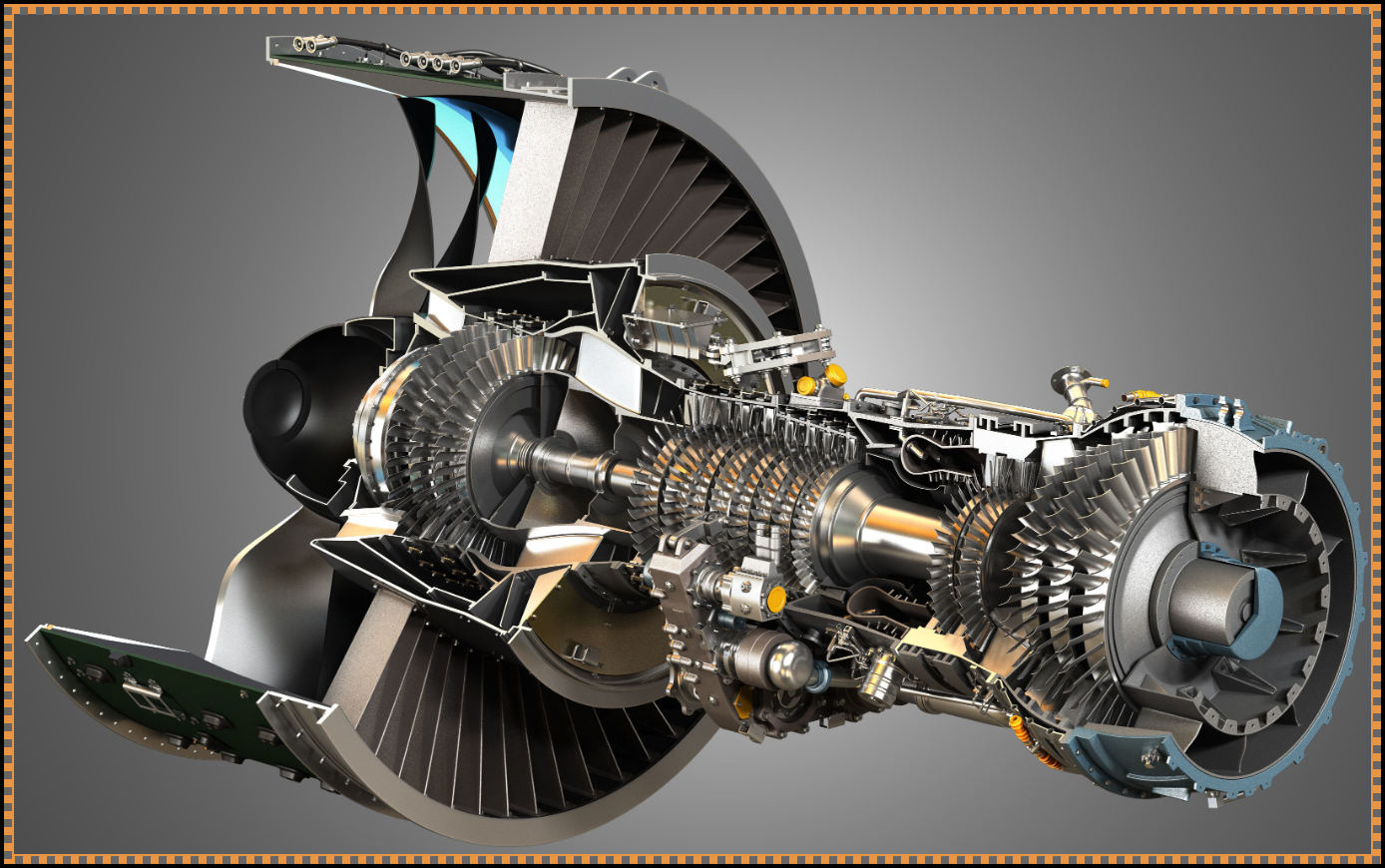

The RTX corporation revealed in an earnings call on July 25 that it was recalling up to 1,200 of its PW1100G Geared Turbofan Engines, built by subsidiary engine-maker Pratt & Whitney, for accelerated inspection.

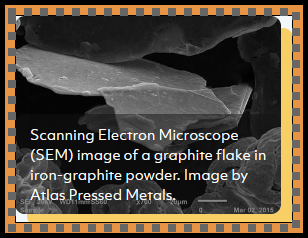

The culprit—MICROSCOPIC CONTAMINANTS DISCOVERED IN THE POWDERED METAL produced at a New York facility. The metal was used for engine’s stage 1 and 2 high-pressure turbine discs, manufactured at a factory in Columbus, Georgia between 2015 and 2021. The impurities expose the components to risk of accumulating micro-cracks in advance of their specified service lives.

Representative microscopic Image, not RTX

The flaws were first detected in a BROKEN DISC ON A VIETNAMESE A321CEO AIRLINER using the older IAE V2500 turbofan—the product of a joint venture with Pratt & Whitney. However, in mid-July, Pratt & Whitney determined that they weren’t comfortable estimating the risk posed by the powdered metal to its latest-generation PW1100G engines, and that they merited an accelerated inspection schedule.

At present, RTX (formerly known as Raytheon) plans to inspect 200 of the oldest higher-priority engines by September. An estimated 1,000 more engines may require inspection in the year to follow—though the final number could end up below or above that, depending in part on the findings of the initial tranche of inspections. Two PW1100G-JM engines are used in some of Airbus’s A320neo and A321neo jetliners, which closely rival the Boeing 737 for the crown of most prolific jetliners in service. The estimated 1,200 engines amount to 40% of the roughly 3,000 PW-1100Gs delivered.

John keeble//Getty Images

Each inspection requires two months to dismantle the engine, replace the discs (if flawed), and reassemble them. Based on prior experience looking for flawed discs in 3,000 engines, Pratt & Whitney is optimistic that only around 1% of the discs will require immediate replacement. That recall (or ‘shortened inspection intervals’ as the firm put its) still risks disrupting operations by carriers that operates PW1100G-equipped jetliners, as in-service aircraft are taken out of rotation early for inspection. However, the discovered flaws don’t pertain to or affect deliveries of new GTF engines (the plant corrected them in 2021) or production of new aircraft.

RTX’s executive Greg Hayes conceded during the call that the “disappointing” problem would be expensive to fix and would impact customers—though he insisted that it didn’t amount to an “existential problem” for either Pratt & Whitney or RTX. Nonetheless, investor backlash led to a 10% drop in RTX share value after the recalls were announced, while Airbus took a 2.5% hit. RTX itself reduced its estimated 2023 cash flow by a half billion dollars to a net $4.3 billion.

The A320’s most numerous operator is India’s IndiGo, with 143 aircraft. Other major operators that received A320neos and A321neos are found in the U.S. (Delta, Jet Blue, Spirit, United, Hawiian), China (including Air China, Shenzhen and Sichuan Airlines), Hungary, Japan, Mexico, Turkey, and Vietnam. America Airline’s large A320 and A321 fleet, however, uses the rival CFM LEAP engine for propulsion.

Clash of the turbofans: GTF versus LEAP

The two predominant jetliners in production today are the Boeing 737MAX and Airbus A320neo series of single-aisle airliners. While the 737MAX is fitted with the LEAP engine developed by market leader CFM International (a French-American joint venture), the A320neo can be fitted with either LEAP turbofans or the Geared Turbofan (GTF) developed by Pratt & Whitney.

LEAP-1A turbofan engines produced by joint venture CMF International at the Safran factory near Paris on June 16, 2023. The LEAP-1 is the main competitor of Pratt & Whitney’s Geared Turbofan (GTF) series of engines.

GONZALO FUENTES//Getty Images

Both high-bypass turbofans were pegged as offering fuel efficiency improvements around 16%, which adds up to huge savings over older aircraft. Given that a typical jetliner might fly 3,000 hours annually, improving fuel efficiency and lowering operating costs are the name of the game in commercial jet travel. Carbon-emission reduction benchmarks and offsets seeking to slow down climate change further multiply the value of such efficiencies. Though LEAP and GTF both incorporate many advanced technologies, such as new wear-resistant coatings, GTF is overall less conventional. They introduced a gearbox that allows the fan and the spool of the engine to turn at different, more optimal speeds.

This content is imported from youTube. You may be able to find the same content in another format, or you may be able to find more information, at their web site.

………..

CONTRIBUTOR

Sébastien Roblin has written on the technical, historical, and political aspects of international security and conflict for publications including 19FortyFive, The National Interest, MSNBC, Forbes.com, Inside Unmanned Systems and War is Boring. He holds a Master’s degree from Georgetown University and served with the Peace Corps in China. You can follow his articles on Twitter.

————————————————–