Centuries Old Metallurgical Research produces PROMISING INNOVATION

Two recent articles highlighted that metallurgy has the potential to revolutionize aerospace engineering.

- A German professor and his team at KIT are developing a composite that is capable of sustaining temperatures of as much as 2,000 Celsius. This SUPERALLOY promises to raise the internal temperatures of turbine engines that will reduce carbon emissions.

- University of Alabama professor and his laboratory are designing a system that can be embedded in stuctures and that will not only detect faults, but also able to repair the fractures. NASA thinks that this research will revolutionize maintenance, repairs and even the MX concept of continuous airworthiness.

These are, to say the least, INCREDIBLE research results in a science/engineering field that has been driving innovations for almost 7 centuries. Georg Bauer (Georgius Agricola) is generally recognized as a, if not THE, pioneering metallurgy scholar His landmark work, De Re Metallica, published posthumously in 1556, systematically documented mining techniques, ore processing, and smelting methods. It remained the authoritative text on metallurgy for nearly two centuries.

What these German and American professors have accomplished derives from Herr Bauer!!! Even more contemporary experts, say EVEN 10-20 years ago, likely would not have predicted a SUPER COMPOSITE[1] ALLOY or SELF-HEALING METAL !!!

The lesson of these developments is that PURE BASIC RESEARCH, while not always with clear results, IS ESSENTIAL TO CONTINUED INNOVATION IS AVIATION. As an unknown commentator is said to have articulate:

“Metallurgy is the silent architect behind every aerospace breakthrough—without advances in materials, engines wouldn’t roar and wings wouldn’t soar.” – Unknown

Scientists Forge New “Superalloy” That Could Revolutionize Jet Engines and Power Plants

October 16, 2025 Scientists have developed a groundbreaking chromium–molybdenum–silicon alloy capable of withstanding temperatures far beyond the limits of conventional superalloys. Credit: SciTechDaily.com

By Karlsruhe Institute of Technology

A newly developed material with exceptional high-temperature resistance shows strong promise for use in energy-efficient aircraft turbines.

Metals that can endure extremely high temperatures are essential for technologies such as AIRCRAFT ENGINES, gas turbines, and X-ray equipment. Among the most heat-resistant are refractory metals like tungsten, molybdenum, and chromium, which melt at or above 2,000 degrees Celsius.

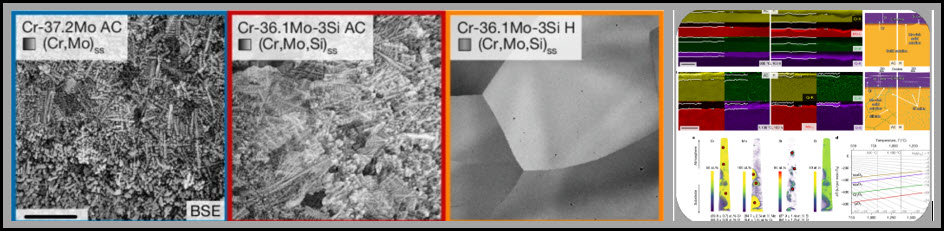

Despite their impressive thermal stability, these metals face major drawbacks. They become brittle at room temperature and oxidize rapidly when exposed to oxygen, leading to material failure at only 600 to 700 degrees Celsius. Because of this, they can be used effectively only under complex vacuum conditions (for example, as X-ray rotating anodes).

To overcome these obstacles, engineers have long relied on nickel-based superalloys for components that must function in air or combustion environments at high heat. These alloys have become the standard choice for gas turbine construction and similar high-temperature applications.

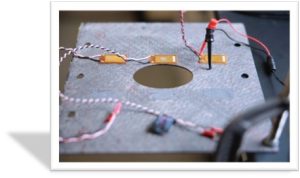

Alloy production by means of arc melting in the material synthesis lab of the Institute for Applied Materials – Materials Science and Engineering. Credit: Chiara Bellamoli, KIT

“The existing superalloys are made of many different metallic elements including rarely available ones so that they combine several properties. They are ductile at room temperature, stable at high temperatures, and resistant to oxidation,” explains Professor MARTIN HEILMAIER from KIT’s Institute for Applied Materials – Materials Science and Engineering.

“However – and there is the rub – the operating temperatures, i.e., the temperatures in which they can be used safely, are in the range up to 1,100 DEGREES CELSIUS MAXIMUM. This is too low to exploit the full potential for more efficiency in turbines or other high-temperature applications. The fact is that the efficiency in combustion processes increases with temperature.”

A Chance for a Technological Leap

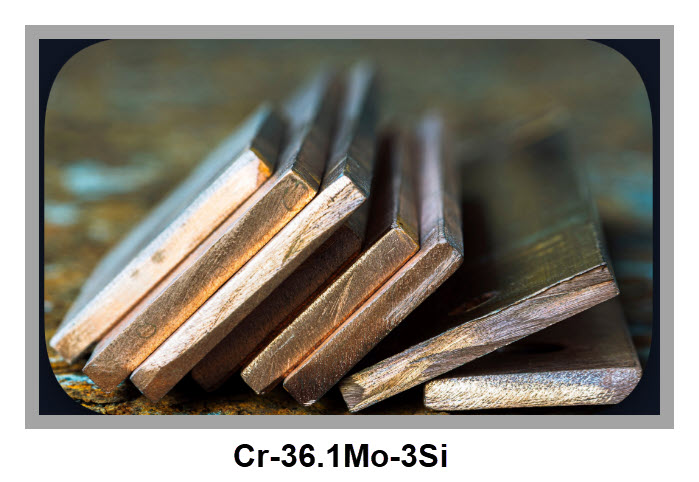

This limitation existing with the materials available today was the starting point for Heilmaier’s working group. Within the “Materials Compounds from Composite Materials for Applications in Extreme Conditions” (MatCom-ComMat) research training group funded by the German Research Foundation (DFG), the researchers succeeded in developing a NEW ALLOY made of CHROMIUM, MOLYBDENUM, AND SILICON[2].

This refractory metal-based alloy, in whose discovery Dr. Alexander Kauffmann, now professor at the Ruhr University Bochum, played a major role, features hitherto unparalleled properties.

“It is ductile at room temperature, its melting point is as high as about 2,000 degrees Celsius, and – unlike refractory alloys known to date – it oxidizes only slowly, even in the critical temperature range. This nurtures the vision of being able to make components suitable for operating temperatures substantially higher than 1,100 degrees Celsius. Thus, the result of our research has the potential to enable a real technological leap,” says Kauffmann.

This specifically remarkable as resistance to oxidation and ductility still cannot be predicted sufficiently to allow a targeted material design – despite the great progress that has been achieved in computer-assisted materials development.

More Efficiency, Less Consumption

“In a turbine, even a temperature increase of just 100 degrees Celsius can reduce fuel consumption by about five percent,” explains Heilmaier.

“This is particularly relevant to aviation, as airplanes powered by electricity will hardly be suitable for long-haul flights in the next decades. Thus, a significant reduction of the fuel consumption will be a vital issue. Stationary gas turbines in power plants could also be operated with lower CO₂ emissions thanks to more robust materials. In order to be able to use the alloy on an industrial level, many other development steps are necessary,” says Heilmaier.

“However, with our DISCOVERY IN FUNDAMENTAL RESEARCH, we have reached an important milestone. Research groups all over the world can now build on this achievement.”

Reference: “A ductile chromium–molybdenum alloy resistant to high-temperature oxidation” by Frauke Hinrichs, Georg Winkens, Lena Katharina Kramer, Gabriely Falcão, Ewa M. Hahn, Daniel Schliephake, Michael Konrad Eusterholz, Sandipan Sen, Mathias Christian Galetz, Haruyuki Inui, Alexander Kauffmann and Martin Heilmaier, 8 October 2025, Nature.

DOI: 10.1038/s41586-025-09516-8

How self-healing aircraft materials could revolutionise aviation safety and maintenance

Jay Menon

October 17, 2025

In Alabama, engineers are creating aircraft materials that can sense and heal damage mid-flight — a breakthrough that COULD REDEFINE AVIATION SAFETY AND MAINTENANCE.

When a hairline crack appears in the wing of an aircraft at 35,000 feet, the consequences can be catastrophic. But what if the aircraft could sense that damage and fix it before anyone even knew it existed?

That question is no longer theoretical. In a laboratory at the University of Alabama, aerospace engineers are developing aircraft materials that can detect and heal structural damage in real time.

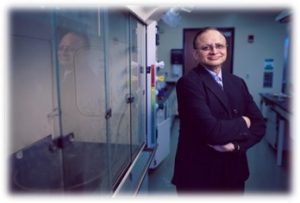

The research, led by Professor Samit Roy, the William D. Jordan Professor of Aerospace Engineering and Mechanics, could one day allow airframes to REPAIR THEMSELVES MID-FLIGHT, a breakthrough that promises to redefine aviation safety and maintenance.

“Nature already does this; our bodies detect and heal damage,” Roy explains. “We’re simply applying that concept to engineered systems.”

His team’s work, housed in the Advanced Composite Materials Lab and the Advanced Materials Processing Lab, focuses on creating smart composite structures: MATERIALS EMBEDDED WITH SENSORS THAT ACT LIKE A NERVOUS SYSTEM, CONTINUOUSLY MONITORING STRESS AND STRAIN.

When damage occurs, these sensors trigger a healing response, restoring structural integrity without human intervention.

How self-healing aircraft materials work

The principle may sound futuristic, but its inspiration is ancient.

“A COMPOSITE,” Roy reminds his students, “is any material composed of more than one constituent. The oldest known composite is wood fibres surrounded by a cellulose matrix. EVEN THE WRIGHT BROTHERS BUILT THEIR FIRST AIRCRAFT USING WOOD AND FABRIC.”

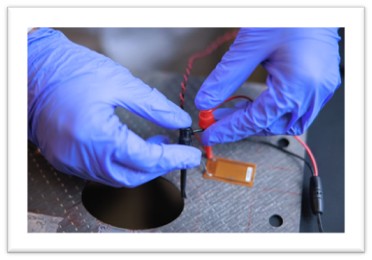

Today, his lab uses carbon fibre-epoxy composites enhanced with shape-memory polymers and thermoplastic powders.

When a crack forms, the embedded sensors detect it, generate heat, and activate the thermoplastic material, which flows into the fissure and re-solidifies. The damaged area effectively heals itself, restoring strength within minutes.

Photo: University of Alabama

“The idea came to us more than a decade ago while we were improving damage detection in composites,” Roy says. “Eventually, we asked — what if we could also heal that damage using the same network of sensors?”

Initial funding from the US Air Force helped move the concept from theory to prototype. Since then, Roy’s team has published a series of studies and filed patents as they refine the system for full-scale aircraft applications.

AI and digital twins: the brain behind the healing

Behind the materials lies a digital brain. Roy’s system integrates artificial intelligence with digital twin technology — virtual models that mirror real aircraft and constantly update with live sensor data. He calls it a “digital twin on steroids.”

This model not only predicts structural stress but also determines the severity of damage and initiates a healing response automatically. In effect, the aircraft becomes aware of its own condition and responds before a fault can escalate into failure.

The approach aligns with what NASA predicted in a 2011 study on self-healing polymer composites, which found that “autonomous sensing and repair” could transform aerospace maintenance by reducing inspection costs and extending service life.

Roy’s work now turns that projection into practice, enabling condition-based maintenance systems that fix themselves instead of waiting for scheduled checks.

Why self-repairing technology matters for defence and space

The implications reach far beyond commercial airliners. In space exploration, where human intervention is impossible, or in combat zones, where repairs may be delayed for days, self-healing materials could be life-saving.

“This doesn’t eliminate maintenance,” Roy cautions, “but it buys time. Especially in remote or hostile environments, that time can be the difference between recovery and loss.”

Photo: University of Alabama

A crack that might once have grounded an aircraft could now repair itself in flight. For NASA, which has studied such systems for spacecraft hulls and lunar habitats, and for military operators managing fleets in austere conditions, the potential is enormous.

Roy’s research also serves as a living classroom in innovation. His labs have supported multiple doctoral dissertations, and students work directly on the technology’s evolution — from developing nanocapsule-based healing agents to testing AI-driven response systems.

“Students gain hands-on experience in advanced research and learn how to apply theoretical knowledge to real-world aerospace challenges,” Roy says. “It’s rewarding to see their growth and their contribution to a genuinely new field.”

From lab to flight: when will self-healing aircraft take off?

For now, the technology remains in the testing phase. SCALING self-healing materials to entire airframes involves major challenges — including cost, manufacturability, and certification. But industry interest is growing, especially as airlines and defence agencies seek ways to extend fleet life and reduce downtime.

▬►A NASA REVIEW OF SMART STRUCTURES AND SELF-REPAIRING MATERIALS NOTED THAT INTEGRATING SENSING AND HEALING FUNCTIONS “COULD REDEFINE STANDARDS OF RELIABILITY IN AEROSPACE DESIGN.”◄▬

Roy’s work is doing exactly that — not through science fiction, but through the painstaking process of engineering.

Photo: University of Alabama

From the Wright brothers’ wooden biplane to today’s carbon fibre jets, every generation of aircraft has been built on the same principle: lighter, stronger, safer. The next revolution may be one of resilience — machines that don’t just withstand stress but recover from it.

As Roy sees it, this evolution brings aviation closer to life itself. “We’re making structures that can feel, react, and respond,” he says. “They won’t just fly — they’ll adapt.”

And in that single leap from machine to organism, the idea of self-healing flight might just represent the most human advance in aerospace yet.

[1] “A COMPOSITE,” Roy reminds his students, “is any material composed of more than one constituent. The oldest known composite is wood fibres surrounded by a cellulose matrix. EVEN THE WRIGHT BROTHERS BUILT THEIR FIRST AIRCRAFT USING WOOD AND FABRIC.”

[2] The ductile chromium–molybdenum alloy you’re referring to is a single-phase alloy with the following atomic composition:

- Cr-36.1Mo-3Si (at.%)

This means the alloy consists of:

- 1 atomic percent molybdenum (Mo)

- 3 atomic percent silicon (Si)

- The remainder (60.9 atomic percent) is chromium (Cr).

This composition was specifically engineered to resist high-temperature oxidation (up to 1,100 °C) while maintaining ductility at room temperature—an uncommon combination for refractory-element-based materials. The addition of silicon plays a key role in stabilizing the oxide scale and mitigating pesting and nitridation effects that typically plague Mo and Cr at elevated temperatures.