Boeing’s Tear Down Laboratories- looking for the right stuff?

Boeing News Now published an interesting article about the company’s Boeing Technology Innovation (BTI) teardown labs – in Bangalore, Seattle, and St. Louis. The piece explains how the technicians examine wings, fuselages, parts and systems The author repeatedly mentions the process’ benefits—

-

efficiency,

-

cost mitigation,

-

market solutions,

-

financial decisions

-

savings through optimal cost and design recovery.

-

and

-

price creep of components

In the almost 500 words, only one phrase “HIGHEST SAFETY STANDARDS” cites what MUST BE BOEING’s #1 goal.

Passion for Aviation Safety is and should be evident in the EVERYTHING THE AEROSPACE ENTERPRISE DOES. Leadership must instill that culture by word, but most importantly by example. If this “crusade” is successful, that focus will be reflected in everywhere- yes, signs are important, but true attention to detail will be demonstrated in what might be considered MINUTIAE.

Tearing down Boeing’s own products is an expensive and effective exercise. However, its forensic pathologist engineers are looking at their work PRIMARILY to find cost savings, or so the company’s article says. If Boeing has achieved true SAFETY CULTURE (and all of its reports says the company has[1]), these technicians’ pathology would emphasize examining these “bones” to identify positive safety improvements. This report does not mention that these tear downs have resulted in any SAFETY enhancements of the Boeing aircraft; this is the exactly the minutiae that would show truly effective change from its old financial priorities to a new safety/quality passion.

How tearing down helps Boeing build better

By analyzing dismantled aircraft parts, teammates in teardown

labs drive efficiencies and shape better contract bids.

Much like a surgeon performing a delicate operation, teams working in Boeing teardown labs carefully dissect aircraft components to uncover the keys to IMPROVED PERFORMANCE.

The process allows teardown engineers to collect important product data to design and build EVEN GREATER EFFICIENCY at every stage of the production life cycle.

Across three Boeing Technology Innovation (BTI) teardown labs – in Bangalore, Seattle, and St. Louis – teams study wings, fuselages, and systems, then share their findings across the company. Comparing Boeing products with MARKET SOLUTIONS offers insights into DISTINCTIVE DESIGN ALTERNATIVES.

The labs have contributed to enabling more than $2 billion in COST MITIGATION AND SAVINGS through OPTIMAL COST AND DESIGN RECOVERY.

The benefits:

-

Increases savings for Boeing and customers — Understanding how a product functions enables comparative analysis and benchmarking against off-the-shelf parts.

-

Promotes more efficient design — Allows engineers to refine product design capabilities earlier in the process.

-

Empowers contract bid negotiations — Facilitates discussions based on actual data, effectively curbing price creep of components during bid proposals.

Why it matters: “Teardown labs are essential for driving innovation, cost savings, and competitive advantage, all while ENSURING THAT INNOVATIONS MEET THE HIGHEST SAFETY STANDARDS,” said Syamalarao Gude, Teardown Lab capability leader. “As Boeing advances aerospace technology, the teardown labs drive informed decision-making and promote continuous improvement across the enterprise.”

Much like a surgeon performing a delicate operation, teams working in Boeing teardown labs carefully dissect aircraft components to uncover the keys to IMPROVED PERFORMANCE.

The process allows teardown engineers to collect important product data to design and build EVEN GREATER EFFICIENCY at every stage of the production life cycle.

Across three Boeing Technology Innovation (BTI) teardown labs – in Bangalore, Seattle, and St. Louis – teams study wings, fuselages, and systems, then share their findings across the company. Comparing Boeing products with MARKET SOLUTIONS offers insights into DISTINCTIVE DESIGN ALTERNATIVES.

The labs have contributed to enabling more than $2 billion in COST MITIGATION AND SAVINGS through OPTIMAL COST AND DESIGN RECOVERY.

The benefits:

-

Increases savings for Boeing and customers — Understanding how a product functions enables comparative analysis and benchmarking against off-the-shelf parts.

-

Promotes more efficient design — Allows engineers to refine product design capabilities earlier in the process.

-

Empowers contract bid negotiations — Facilitates discussions based on actual data, effectively curbing price creep of components during bid proposals.

Why it matters: “Teardown labs are essential for driving innovation, cost savings, and competitive advantage, all while ENSURING THAT INNOVATIONS MEET THE HIGHEST SAFETY STANDARDS,” said Syamalarao Gude, Teardown Lab capability leader. “As Boeing advances aerospace technology, the teardown labs drive informed decision-making and promote continuous improvement across the enterprise.”

The St. Louis teardown lab team recently hosted Steve Parker, president and CEO of Boeing Defense, Space and Security (BDS), and Lisa McCoy, BDS chief human resources officer. The visit highlighted successes benefiting Boeing and its customers. (Photo © Boeing)

“Value engineering enables fast turnaround times and significant cost savings,” said SCOTT WALSTON, vice president, Enterprise Technology in BTI. “The teardown labs support supply chains in negotiating better supplier terms and enhance design efficiency and cost-effectiveness.”[credentials and experience should have flagged the safety value of the BTI process].

Spotlight on success:

-

-

-

-

- BTI teardown lab teammates have created more than a million part cost models, which are tools used to understand the cost structure, make informed financial decisions, and enhance overall efficiency.

- Recently, they developed and implemented a numerical control machining process on the F/A-18E/F program. It reduced flow time from 36 hours to 3 hours and enabled $1.4 million in savings over two years.

-

-

-

The teardown team presented a requirements-based T-7 nose cone solution which produced a per unit cost reduction of 30%.

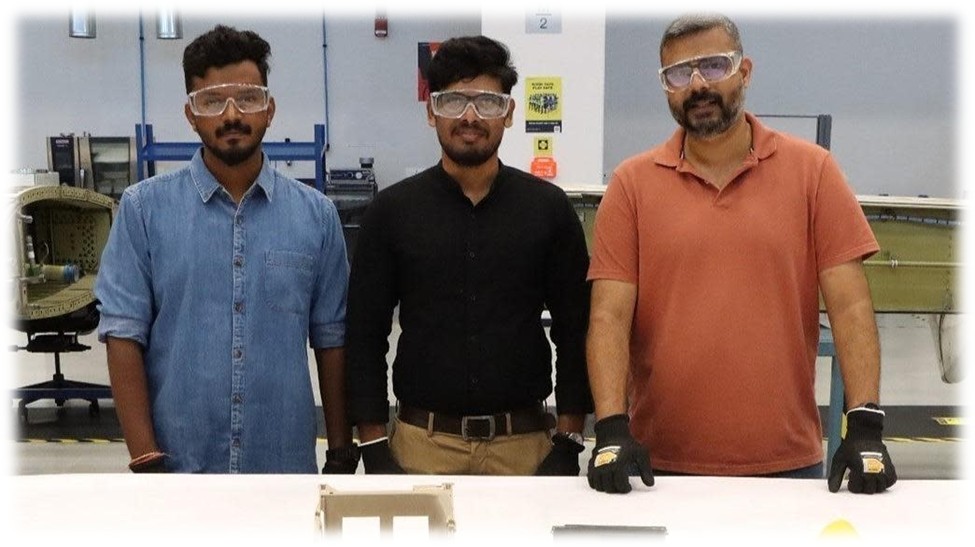

BTI Bangalore teammates

Mithun Ravi, Frankline D, and Karumbaiah Kalapanda Ramesh

examine passenger oxygen panel components.

(Photo © Boeing)[1] This supposition is based on secondary sources and not direct evidence. The past statements by Boeing Boeing’s Safety Officer Report- what’s missing?; https://jdasolutions.aero/blog/reading-between-the-lines-of-the-faas-and-boeings-safety-quality-meeting/; Expert Panel on BOEING ODA- symptoms, no diagnosis- REMEDY?; Mr. Boeing showed that VISIBLE ACTIONS inspire so much more than words!!!

Above, Boeing Technology Innovation teammates examine components in a teardown lab in Bangalore, India. (Photo © Boeing)

Above, Boeing Technology Innovation teammates examine components in a teardown lab in Bangalore, India. (Photo © Boeing)