Boeing Safety engineers to Dhaka, Bangladesh—WHY???

Aviation Safety depends on self-awareness, a significant pillar of Safety Management System’s discipline (SMS). The CEO and MD of Biman Bangladesh Airlines has requested that the Boeing company send at a team of engineers for at least a month to assess the airline’s safety compliance.

Why Boeing?

Such an inspection would ordinarily be a routine function of the Civil Aviation Authority of Bangladesh (CAAB). Unfortunately, the FAA’s International Aviation Safety Assessment (IASA) program does not find that this authority meets International standards[1]. In June 2024, FAA Attaché Daniel Jacob met with the CAAB and they discussed how its compliance could be improves. The country continues to receive technical assistance from FAA and TSA

Again, why Boeing???

On July 2025, government of Bangladesh placed an order for 25 aircraft from Boeing, up from an initial order of 14, as part of negotiations with the Trump administration to lower the proposed export tariff.

It should also be noted that the government has expressed interest in buying Airbus aircraft.

The airline has already completed a self-investigation of its

- maintenance records and operational processes on a flight-by-flight basis, identify root causes, and determine responsibility in case of any negligence or lapse

- Biman’s inventory management system is also underway

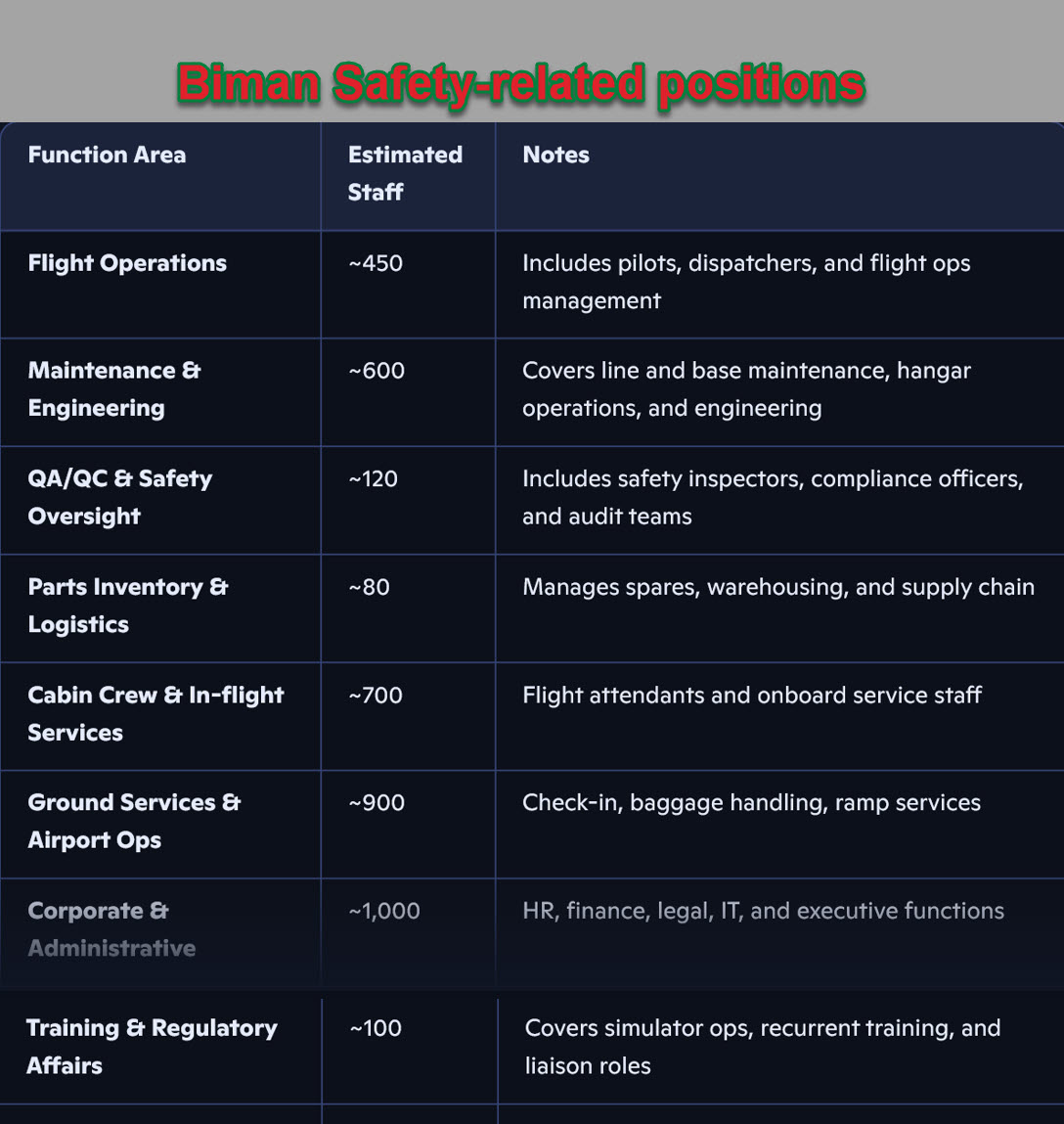

The article does not mention any specific areas to be audited and the Boeing inspectors are trained to find differences between the company’s standards and QA/QC, safety culture and other focus areas of an OEM. To be effective, the external auditors will have to assess (probably on a statistically reliable sample) this range of positions (about 4,000):

What is presumed to be a FREE audit likely cannot produce meaningful results in a month or longer. Yes, Boeing knows airliners, but it HAS NOT OPERATED AN AIRLINE FOR ALMOST 100 YEARS. It certainly is aware of inventory management from a seller’s perspective and it has defined the engineering standards for repairs. But even those insights are not from the perspective of a carrier. The URGENCY of completing a C check or of the replacement of “burst tyre” involve different considerations than the assembly line in a hangar in Renton, WA. Maybe, the Seattle/Illinois/Virginia company might do better by its growing customer client by hiring/paying for an outside consultant that has experience assessing a carrier’s safety compliance.

Biman asks Boeing to send engineers to check safety standard

The national flag carrier has already undertaken a set of immediate and long-term measures aimed at reinforcing safety standards, accountability and operational reliability

A Biman aircraft in Dhaka. Photo: TBS

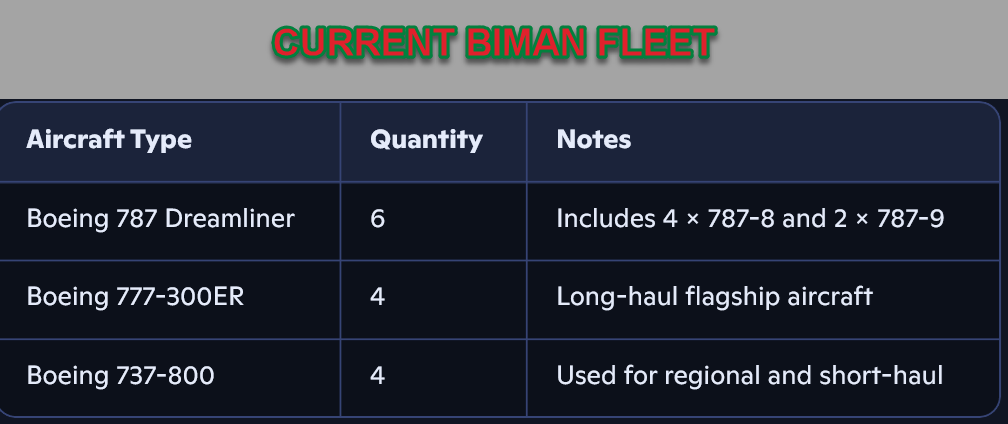

BIMAN BANGLADESH AIRLINES has sought Boeing’s assistance, requesting the US plane manufacturer to send engineers for at least one month to assess safety standards of its Boeing-dominated fleet, following a series of technical glitches reported over the past month.

“We have asked Boeing to send at least two engineers to work with our engineering team for one month,” Biman’s Managing Director and CEO DR SHAFIQUR RAHMAN told BSS today (30 August).

The Biman chief said he has already talked with the Boeing South Asia office in New Delhi and raised its concern over the serious of technical glitches.

“Our engineering team is working very sincerely … we do believe engineers from Boeing will give them a boost,” Rahman added.

The national flag carrier has already undertaken a set of immediate and long-term measures aimed at reinforcing safety standards, accountability and operational reliability.

A FOUR-MEMBER HIGH-POWERED INVESTIGATION COMMITTEE has already been formed to review in detail the technical issues that occurred between 1 July and 13 August last.

The committee will examine maintenance records and operational processes on a flight-by-flight basis, identify root causes, and determine responsibility in case of any negligence or lapse.

“Passenger safety and service quality have been given the “highest priority,” while comprehensive investigations and strict accountability are being ensured for each incident,” Rahman said.

It has been asked to submit its findings within 10 working days with recommendations to prevent recurrence of such problems.

As part of immediate steps, the incident involving a malfunction of the toilet flush on the Dhaka-Abu Dhabi flight has come under investigation.

Meanwhile, CHANGES IN PERSONNEL MANAGEMENT have been made to ensure ACCOUNTABILITY, two officials have been transferred, while disciplinary action has been taken against one engineering officer and a show-cause notice has been served on another in Chattogram.

To enhance technical capacity, Biman has arranged stocking additional aircraft wheels at key outstations, including Jeddah, Dubai, Medina, Dammam, Abu Dhabi and Sharjah so that replacements can be carried out swiftly during emergencies.

Procurement orders for additional wheels have already been placed.

The airline said an INQUIRY into the tire burst incident in Jeddah has been ordered under the supervision of the Director (Flight Operations), while direct supervision of maintenance has been reinforced by the Director (Engineering and Material Management) and Chief Engineers.

In addition, a special night maintenance shift has been introduced from 18 August to strengthen round-the-clock monitoring.

A comprehensive review of Biman’s inventory management system is also underway, including discussions with Boeing on revising the Component Services Program (CSP) list and reassessing the Recommended Spare Parts List (RSPL).

Tailored Part Packages (TPP) is being reviewed to ensure procurement aligns with actual usage data.

RECURRENT TRAINING FOR ENGINEERS has been initiated, while recruitment of new apprentice mechanics has started as part of long-term capacity building to strengthen in-house expertise and technical manpower, Biman officials said.

[1] ICAO’s Universal Safety Oversight Audit Programme (USOAP) provides an “Effective Implementation” (EI) score across eight critical elements of safety oversight