Spirit AeroSystems – Boeing key questions to be asked and from which to learn

A lawsuit, see below article, alleges that Spirit AeroSystems disregarded complaints of its quality personnel that defects were present in the company’s production lines, although the B737 Max 8 plug door was not specified. Spirit did not reply to the author; so, the company’s position on these serious safety concerns are not yet known.

Spirit is a major subcontractor to Boeing; what FAA requirements apply to their deliveries to Boeing?

Not yet applicable, but important to note: On January 11,2023 the Federal Aviation Administration (FAA) has issued a Notice of Proposed Rulemaking (NPRM) titled “Safety Management Systems” This proposed rule would extend the requirement for an SMS, inter alia, to all production certificate (PC) holders that are holders or licensees of a type certificate (TC) for the same product, and holders of a TC who license out that TC for production. The NPRM has not yet been promulgated in final form. Prior to this globally recognized state-of-art standard being imposed by the FAA, Boeing’s website makes frequent reference to the company’s adoption of SMS.

The existing QA/QC requirements for this PC holder’s review of its supplier begins with a rule that production certificate holders qualify and inspect contractors. The FAA required Boeing to allow the FAA to inspect its quality system, facilities, technical data, and any manufactured products or articles and witness any tests, including any inspections or tests at a supplier facility, necessary to determine compliance. The holder of a production certificate must maintain the quality system in compliance with the data and procedures approved for the production certificate. The FAA provides guidance for persons who conduct ANNUAL AND PROGRESSIVE INSPECTIONS and approve major repairs and/or major alterations of aircraft holding or eligible to hold a U.S. type certificate.

Boeing has devoted substantial content on its websites to visibly proclaim its adoption of this tool designed to reduce risks, identify flaws early and be proactive. While using corporate information on put on the internet is not definitive, what it does highlight does provide some indication of the messages that it wants its customers, employees, investors, and regulators to SEE. A search of the Wichita subcontractor’s page TODAY did not identify material with “safety” or “SMS” or similar term. This image is a summary of the main commercial section:

Its Board of Directors and Senior Executives evidence experience and knowledge relevant for the company’s mission. The CEO for the times mentioned in the lawsuit resigned in October 2023 and Patrick Shanahan, a Boeing engineer 1986-2017, was named as his interim replacement. The officer with direct responsibility over these issues, Bill Brown, senior vice president of Quality for Spirit AeroSystems, has the qualifications for this critical safety function. As previously mentioned, the as-of-yet non-mandatory SMS discipline has escaped digital searches.

What is most curious here is an anomaly—the suit claims that at least 3 concerns were raised by relevant Spirit AeroSystem professionals, but ????

- UNKNOWN: what did the senior management team know? If they knew, what action if any did they take? If they ignored these flags, why?

- UNKNOWN: did Spirit AeroSystems report these incidents to Boeing?

- UNKNOWN: during 2023 did Boeing and/or the FAA conduct and inspections of the Wichita and other factories?

- UNKNOWN: Li et al v. Spirit AeroSystems Holdings, Inc. et al was filed. What did the Company, Boeing and the FAA do in response to those serious claims of defects?

Certainly, the FAA and the NTSB and hopefully, Boeing are asking these same questions. In the spirit of SMS, all will learn the depths to which a TC holder must (i) examine the safety standards/culture of a contractor prior to signing and (ii) determine some quantitative metric which can be applied during fabrication assuring that the production line performance is meeting the requirements of the production certificates, contracts, specifications, certificates from the contractor to the PC and the quality inspection by the PC at intake AND installation.

THIS MUST BECOME A LESSON NOT A BATTLE!!!

Federal suit claims Spirit AeroSystems concealed serious defects to maximize production

Officials at Spirit AeroSystems disregarded safety concerns raised by former employees and instructed them to undercount defects they found on plane fuselages; a federal lawsuit alleges.

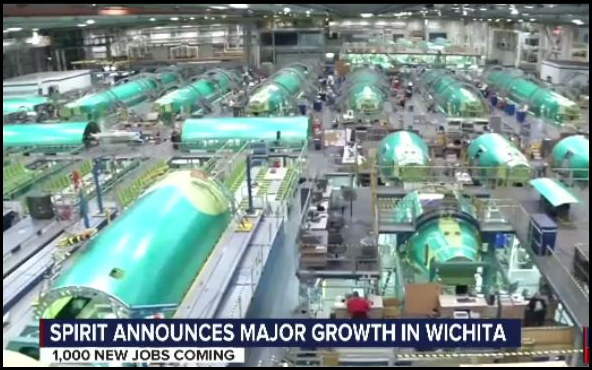

The Wichita manufacturing giant sustained its latest round of negative attention when it was identified as the Boeing supplier responsible for producing and installing the door plug that blew off of an Alaska Airlines 737 MAX mid-flight, forcing an emergency landing on Jan. 5. Less than a month before the faulty plug left a gaping hole in the fuselage of the plane, documents were filed in federal court alleging “WIDESPREAD QUALITY PROBLEMS AT SPIRIT.”

“The class action lawsuit is brought by Spirit shareholders who say they suffered financial damage when company stock lost value after officials misrepresented company operations and withheld information about quality control issues.

Although door plug manufacturing defects are not specifically mentioned in the suit, it does cite the routine presence of foreign object debris in Spirit products, missing fasteners, peeling paint, and poor skin quality.

“Such constant quality failures resulted in part from Spirit’s culture which prioritized production numbers and short-term financial outcomes over product quality,” the complaint states.

Spirit has not yet filed a response in court. In a written statement provided to The Eagle, the company pushed back against accusations of wrongdoing.

“Spirit strongly disagrees with the assertions made by plaintiffs in the amended complaint and intends to vigorously defend against the claims. Spirit will not comment further as to the pending litigation.”

Court filings cite the experiences of former employees who say they were threatened and thwarted when they attempted to alert their superiors to defects.

In 2022, quality auditor Joshua Dean identified mis-drilled holes on a 737 MAX aft pressure bulkhead, which plays a critical role in maintaining cabin pressure during flight. According to the suit, Dean filed a written report to his manager and alerted multiple supervisors, but SPIRIT CONCEALED THE DEFECT FROM BOEING AND INVESTORS UNTIL IT WAS REVEALED IN INDEPENDENT REPORTING 10 MONTHS LATER.

Dean was fired in April 2023 after continuing to raise concerns about defects, the complaint alleges.

A separate quality inspector who is not identified by name filed an ethics complaint outlining “the excessive amount of defects” that he and his team had identified, noting that they were instructed to misreport the numbers of defects in a way “which would be falsifying the documentation.”

A third quality auditor, also unnamed, is quoted as saying “auditors repeatedly found torque wrenches in mechanics’ toolboxes that were not properly calibrated.”

“THIS WAS POTENTIALLY A SERIOUS PROBLEM, AS A TORQUE WRENCH THAT IS OUT OF CALIBRATION MAY NOT TORQUE FASTENERS TO THE CORRECT LEVELS, RESULTING IN OVER TIGHTENING OR UNDER-TIGHTENING THAT COULD THREATEN THE STRUCTURAL INTEGRITY OF THE PARTS IN QUESTION,” THE COMPLAINT STATES.

According to multiple former employees cited in court filings, Boeing placed Spirit on probation between 2018 and 2021 due to persistent quality control issues.

Spirit did not respond directly to an Eagle inquiry asking whether the company was indeed placed on probation, providing only the written statement responding to the lawsuit.

Former Spirit CEO Tom Gentile, who resigned his post in October, and current CFO Mark Suchinski are listed as co-defendants in the class action lawsuit.

(c)2024 The Wichita Eagle (Wichita, Kan.) Distributed by Tribune Content Agency, LLC.