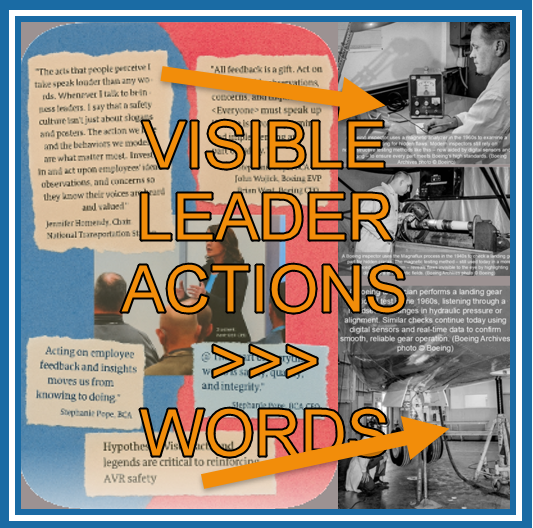

Mr. Boeing showed that VISIBLE ACTIONS inspire so much more than words!!!

Legends are the building blocks that reinforce and/or reestablish AVIATION SAFETY CULTURE. Below is an excellent example of Boeing’s recounting A past visible act by its founder that advances the company’s QC/QA procedures & practices, systems, reporting mechanisms/protected, rewards and beyond. It’s the STUFF OF WHICH LEGENDS ARE MADE.

The FIRST such act was by the company’s founder, Bill Boeing, walking amongst the workers, actually paying attention to what they were doing and with what and grabbing a structural wing rib made of spruce. The head of this nascent aircraft manufacturer knew enough of the specifications for the small but safety significant part of the plane that he tossed it as being failing to meet the part’s requirements. THAT SET THE STANDARD FOR QUALITY for his young aircraft manufacturer forever. PROOF: this simple ACT by the LEADER is cited in the article, over 100 years later, as an essential principle of Boeing’s SAFETY Culture.

This exposition of a series of examples about the Culture set by Mr. Boeing was likely written because of the OEM’s recent deficiencies in managing risk. A simple gesture may seem meaningless or not noteworthy, but the literature, on creating and maintaining uniform attention to such details, suggests that such a visible demonstration by a leader is incredibly inspiring; the experts say that Acts and Legends Matter:

The power of storytelling and organizational narratives

Legends and stories, often rooted in these visible acts, are a fundamental way that safety values are transmitted and reinforced within an organization. Academic research demonstrates that storytelling is a powerful tool for shaping safety intentions and behavior.

- Narrative over data: Research shows that while data is important, narratives are more effective at building emotional connections and fostering a shared consciousness around safety. Stories of a specific time and place where a leader or coworker took a visible action for safety are more memorable and impactful than a statistical report.

- Solidifying cultural identity: Stories and legends give employees a cultural identity and a sense of shared purpose. For example, the story of “the time our CEO stopped the entire production line because of a minor safety concern” can become a powerful legend that defines the organization’s commitment to safety for years to come.

- Encouraging behavioral change: Narratives can help employees process and internalize safety values, encouraging a proactive approach to safety management. Sharing experiences openly, especially regarding near-misses or critical decisions, helps the workforce collectively work toward solutions and develop a more resilient culture.

The FARs are written, by necessity, in dry, precise language and are not meant to inspire. However, the expectations of the FAA and all the world’s safety regulators are that those charged with implementing them or enforcing them will translate that lifeless prose into words that motivate, that imbue an intense awareness of risks and an openness to excel in this mission. The FAA’s Safety Management Systems charges the ACCOUNTABLE EXECUTIVE (AE),per the Federal Aviation Regulation (14 CFR § 5.25(a)(b)), bears the primary mission to lead the organization’s safety culture. Here is the relevant section of Part 5:

(a) Designation of the accountable executive. The CERTIFICATE HOLDER MUST IDENTIFY AN ACCOUNTABLE EXECUTIVE WHO, IRRESPECTIVE OF OTHER FUNCTIONS, SATISFIES THE FOLLOWING:

(1) Is the final authority over operations authorized to be conducted under the certificate holder’s certificate(s).

(2) Controls the financial resources required for the operations to be conducted under the certificate holder’s certificate(s).

(3) Controls the human resources required for the operations authorized to be conducted under the certificate holder’s certificate(s).

(4 RETAINS ULTIMATE RESPONSIBILITY FOR THE SAFETY PERFORMANCE OF THE OPERATIONS CONDUCTED UNDER THE CERTIFICATE HOLDER’S CERTIFICATE.)

(b) Responsibilities of the accountable executive. The accountable executive must accomplish the following:

(1) Ensure that the SMS is PROPERLY IMPLEMENTED AND PERFORMING IN ALL AREAS of the certificate holder’s organization.

(2) Develop and sign the safety policy of the certificate holder.

(3) Communicate the safety policy throughout the certificate holder’s organization.

(4) Regularly review the certificate holder’s safety policy to ensure it remains relevant and appropriate to the certificate holder

(5) REGULARLY REVIEW THE SAFETY PERFORMANCE OF THE CERTIFICATE HOLDER’S ORGANIZATION AND DIRECT ACTIONS NECESSARY TO ADDRESS SUBSTANDARD SAFETY PERFORMANCE IN ACCORDANCE WITH § 5.75.

Experience with AEs throughout US carriers has identified that leaders with these attributes define the specific daily activities that reinforce SAFETY CULTURE at all levels of the enterprise:

“AE” is not just an honorific title, but one who has the personality, skills and authority to succeed in these behaviors

- “The AE is the person most responsible to meet all these specific actions:

- A visible point person who assures that SAFETY > PRODUCTION, that the QA/QC PARAMETERS are well designed and always faithfully executed (this should never be a target for LEAN manufacturing).

- A FAMILIAR FACE on the production line, who stops to ask questions and even probes when she/he perceives something which could be improved.

- A VOICE that speaks in small group meetingsand reinforces the VALUE of submitting POSSIBLE RISKS to the SMS process and especially ideas that may enhance safety.

- A PERSONwho intuitively understands WHEN and HOW BEST TO REWARD POSITIVE SMS behavior. Recognizes the individuals who. Even when action is not immediately adopted, the AE should make all know that the initiative is consonant with SMS.

- An EXPERIENCED professional (ideally an ENGINEER) who is familiar with the Boeing manufacturing processes, who has established trust with the Boeing ODA Unit and with the FAA office surveilling the process.

- One who knows at what the PRESSURE POINTS on the hangar floor are, in the QA/QC design officeand among the design/test engineers. Time spent listening to these is a key to assuring that SAFETY CULTURE exists not just at inception points but 24/7/365.

- An INDIVIDUALwith the stature and expertise to come to the Board to report on the Good and BAD.

The Boeing legend exemplifies that, but curiously Boeing’s designated AE, Stephanie Pope, is not mentioned in the article’s ~800 words.

The Board elected Ms. Pope as Chief Operating Officer in early 2024,and the AE title was appended to her job description. Her appointment was presumed to align with Boeing’s broader efforts to strengthen its safety culture and comply with FAA mandates. As COO, she oversees Boeing’s commercial, defense, and services businesses, giving her the operational scope and authority required by the FAA’s definition of an Accountable Executive.

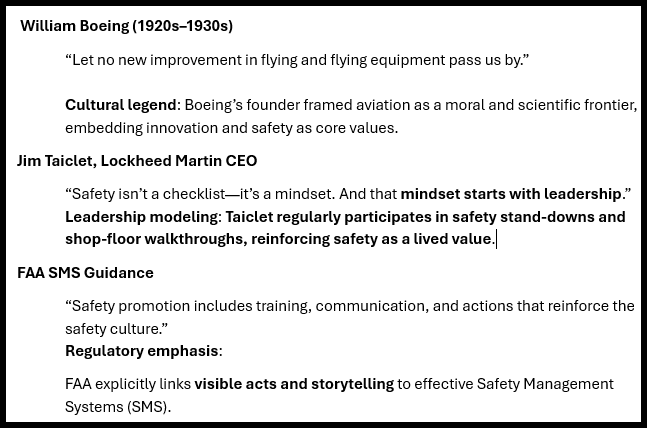

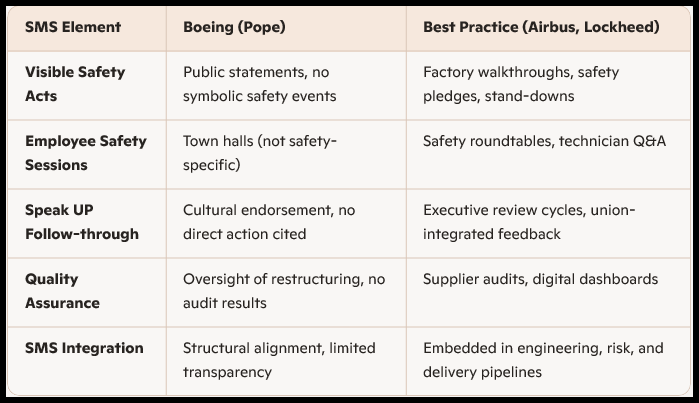

Quotes on the importance of safety as a mission of OEMs-

Copilot AI researched and created this comparative matrix–

Textbooks on SMS include insights like these comments:

A core principle in safety research is that leaders must visibly and actively demonstrate their commitment to safety, a concept often referred to as “VISIBLE FELT LEADERSHIP”. Instead of merely discussing safety in meetings, leaders who perform visible acts—such as personally inspecting equipment, participating in safety walk-rounds, or halting operations due to a safety concern—create powerful, memorable examples.

- Creates tangible evidence: Visible acts move safety from an abstract policy to a concrete, observable priority. This behavior proves that LEADERSHIP’S WORDS ALIGN WITH THEIR ACTIONS, ADDRESSING POTENTIAL EMPLOYEE CYNICISM AND BUILDING TRUST.

- Empowers and legitimizes action: When employees see leaders take decisive action for safety, it legitimizes their own safety-related choices. This can create a chain reaction of behavior, encouraging employees to speak up, report near-misses, and enforce safety protocols themselves.

How a broken piece of spruce set Boeing on its quality journey

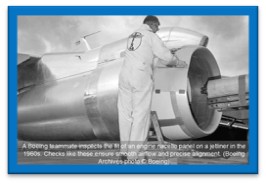

Above: A Boeing inspector examines the interior structure of a 747 fuselage in 1968. (Boeing Archives photo © Boeing)

November 09, 2025, in Commercial

WHEN BILL BOEING VISITED HIS FACTORY ON SEATTLE’S DUWAMISH RIVER IN 1916, HE NOTICED A SET OF STRUCTURAL WING RIBS, MADE FROM SPRUCE, HAD BEEN CUT POORLY. HE KNOCKED THEM TO THE FLOOR, SNAPPED ONE IN HALF AND TOLD THE TEAM, “I, FOR ONE, WILL CLOSE UP SHOP RATHER THAN SEND OUT WORK OF THIS KIND.”

More than a century later, as the company he founded joins manufacturers around the globe in marking WORLD QUALITY MONTH, leaders say Bill Boeing’s principles still define how the company should operate: If it’s built here, it’s built right.

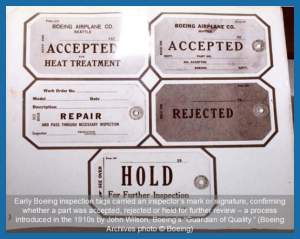

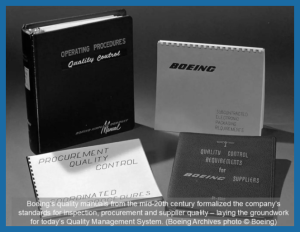

Two years after Bill Boeing’s factory visit, John Wilson – later known as the “Guardian of Boeing Quality” – introduced one of the company’s first inspection systems, using stamped tags to verify each part’s status.

- It was a simple but revolutionary idea: Each stamp became an inspector’s signature – a visible sign of accountability for every part.

“Our tools have evolved, but the principles have not,” said Doug Ackerman, who, as Commercial Airplanes’ current vice president of Quality [click on link for his impressive, safety-relevant education and experience], is charged with carrying on Wilson’s legacy. “WE STILL TAKE PERSONAL OWNERSHIP OF EVERY STAMP OF APPROVAL.”

Built into every job

Until the 1940s, shop employees largely performed quality checks themselves. But BY 1944, Boeing formalized those principles into its first Quality Department. One of its first managers, Elwood Kaiser, captured the philosophy that has lasted through the decades: “QUALITY CANNOT BE INSPECTED INTO OUR AIRPLANES – IT MUST BE PLACED THERE BY THE INDIVIDUAL EMPLOYEE,” HE SAID.

When production surged in the 1950s, as Boeing expanded from wartime manufacturing into the jet age, employees created the Quality Control Club to share ideas and prevent defects. Factory posters reminded teammates that “Quality means reliability” and “Every person’s job is vital to quality.”

That spirit reemerged in the 1980s through Quality Circles – more than 600 employee-led groups met weekly to analyze issues and suggest improvements. Their ideas reduced rework, improved safety and quality, and strengthened Boeing’s reputation for precision.

Boeing’s reputation for precision.

- Today’s EMPLOYEE INVOLVEMENT TEAMS are similar, giving teammates across functions a structured way to share ideas – resulting in thousands of solutions that have improved safety, quality and efficiency.

In the 1990s, Boeing strengthened that foundation with systems like Lean manufacturing and the Quality Management System – part of an industry shift towards efficiency, consistency and customer focus.

“Engaging our teams and listening to their feedback is foundational to lasting quality and continuous improvement,” said Kim Smith, vice president of Quality, Operations & Execution, Global Services. “When we own our work and share ideas, we deliver quality at every step, every time with the excellence and predictability our customers can depend on.”

“Engaging our teams and listening to their feedback is foundational to lasting quality and continuous improvement,” said Kim Smith, vice president of Quality, Operations & Execution, Global Services. “When we own our work and share ideas, we deliver quality at every step, every time with the excellence and predictability our customers can depend on.”

As the company evolved, each decade brought challenges that tested but ultimately made its quality systems stronger.

Production slowdowns and mass layoffs in the 1970s led to workmanship issues that forced teams to rethink how they trained and supported mechanics on the floor.

By the 1980s, process gaps in defense programs prompted improvements to documentation and inspection processes.

Recent years brought more lessons through some of Boeing’s toughest moments – from delivery pauses in 2019 on the KC-46 tanker and 2021 on the 787 Dreamliner, to the 737 MAX grounding in 2019 and door plug accident in 2024. Each came with difficult reflection and significant change, including tighter inspections, clearer accountability and stronger links between Engineering, Manufacturing and Quality.

Over time, the experiences have shown how Boeing’s quality standards remain a constant, even as systems and tools evolve.

A legacy that endures

For more than a century, company leaders say Boeing has demonstrated a focus on quality, and a drive for improvement that continues today.

Teams are rewriting and simplifying thousands of decades-old procedures and using digital tools to improve training and work instructions. Improvement plans based on data from inspections and supplier feedback are also helping teams spot trends and fix issues faster.

- “It’s up to each generation to meet the high bar set by our founder,” said Marisela Reyes, vice president of Quality and Lean for Defense, Space & Security. “Yes, our systems and processes evolve to leverage modern demands and technology, but our standard for quality is absolute.”

The big picture: November is world quality month. Boeing joins quality organizations across the globe during this annual opportunity to share progress and best practices.