May “CITIUS” reinvigorate aviation soon?

The Olympic Motto–“Citius, Altius, Fortius”—stimulated a look at how aviation is striving to be : “Faster, Higher, Stronger”

TODAY’s POST: Two very encouraging articles about airspeeds increasing:.

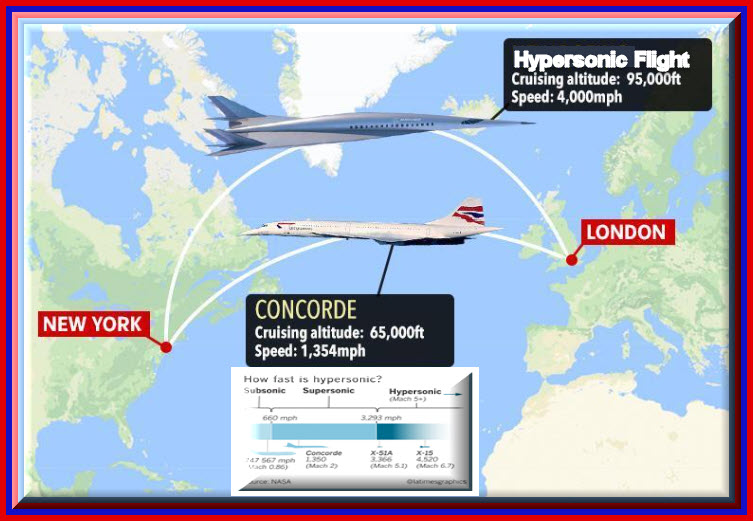

One development points to Mach 7 or 5,187 mph but with an undefined delivery date for Hypersonic flight. University research has found a new dynamic means of controlling a SCRAM jet.

The second article reveals very promising details about an SST, BOOM’s Overture, with a production goal of 2029. The team has brought on important technical partners, has made development progress (in particular an alternative to the Concorde’s droop nose), progress in engine design and test, identification of a materials resource and continued support from an impressive list of airline customers.

The average commercial flight speed has INCREASED ONLY by about 15% over the past 50 years. This unofficial log shows how the speed curve has flattened:

- Douglas DC-3 (1935) had a cruising speed was 207 mph.

- Boeing 707 (1960s) flew at speeds of up to 621 mph.

- The retired Concorde SST flew at 1,341 mph.

- Today’s fastest commercial airliner Boeing 787 Dreamliner: Mach 0.85 (488 knots / 562 mph.

This track record is further diminished by the passenger time consumed getting to/from airports PLUS the hours spent with security agents.

The unmentioned delay risk involves certification. Aerospace technologies, in all the dimensions (powerplants, flight controls, autoland, fuels, materials, structures, avionics, etc.), pose challenges to the world’s certification authorities. Navigating through that regulatory maze will be difficult, but someone who has dealt with those authorities may help.

NASA recently announced that it has commissioned MIT’s Laboratory for Aviation and the Environment to research the environmental impacts of a potential future fleet of supersonic aircraft. That effort and other scientific examinations may have substantial impact on this escalation of global travel. The various SST advocates believe that technology may make these flights compatible.

US scientists master control of hypersonic jet engine with light-based tech

The earlier approach relied on using a pressure sensor to monitor airflow through a supersonic combusting jet engine.

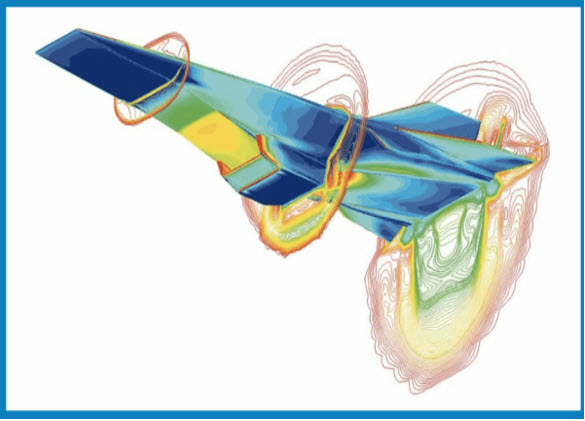

This computational fluid dynamics image from the original Hyper-X tests shows the engine operating at Mach 7.

A new NASA-funded study has revealed for the first time that the AIRFLOW in supersonic combusting jet engines can be CONTROLLED BY AN OPTICAL SENSOR.

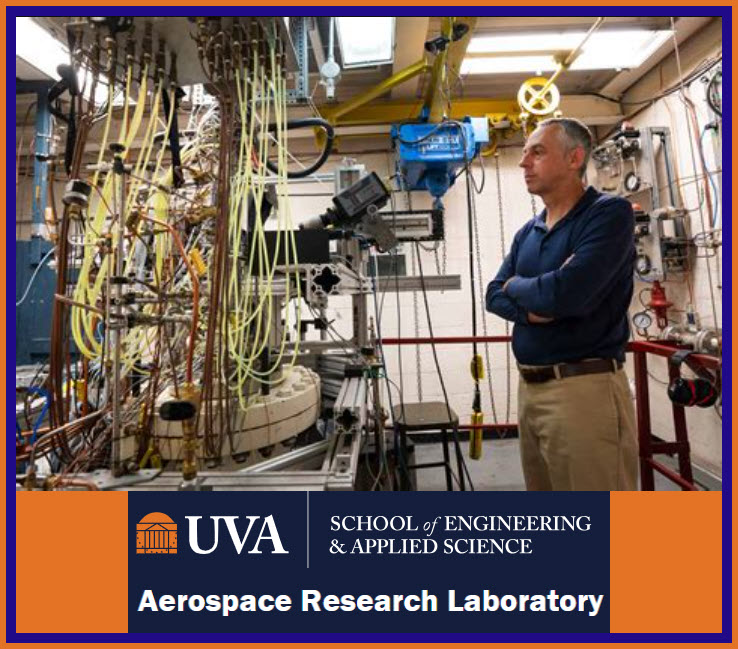

The finding can lead to more efficient stabilization of hypersonic jet aircraft, according to the study carried out by the researchers at the University of Virginia, School of Engineering and Applied Science.

The research allows operators to control airflow at the speed of light when a ‘shock train’ occurs. A shock train is a condition that precedes engine failure within a scramjet engine.

The earlier approach relied on monitoring airflow through a supersonic combusting jet engine using a pressure sensor, while the new breakthrough allows doing the same using an optical sensor.

NASA-funded research

NASA’s hypersonic jet plane ‘Hyper-X set a record for flying faster than any other aircraft in 2004.

The final X-43A unmanned prototype had set the record in the last test held in November 2004, by clocking a world-record speed of Mach 10, which is 10 times the speed of sound. This type of speed had only been achieved by a rocket previously.

This breakthrough had led to a major shift in jet development – by allowing the leap from ramjets to more efficient scramjets. Although the hypersonic proof of concept was successful, the MAIN CHALLENGE WAS achieving engine control, because the tech relied on old sensor approaches.

However, this new breakthrough by UVA brings some hope for the future X-plane series which can travel at hypersonic speeds.

Apart from showing that airflow in supersonic combusting jet engines can be controlled by an optical sensor, the NASA-funded study also achieved ADAPTIVE CONTROL of a scramjet engine.

According to the researchers, adaptive engine control systems RESPOND TO CHANGES IN DYNAMICS to keep the system’s overall performance optimal.

PROFESSOR CHRISTOPHER GOYNE, director of the UVA Aerospace Research Laboratory, said that the country’s aerospace priorities since the 1960s has been to build single-stage-to-orbit aircraft that fly into space from horizontal takeoff like a traditional aircraft and land on the ground like a traditional aircraft.

“Currently, the most state-of-the-art craft is the SpaceX Starship. It has two stages, with vertical launch and landing. But to optimize safety, convenience and reusability, the aerospace community would like to build something more like a 737,” Goines said optical sensors could be crucial for hypersonic aircraft

“It seemed logical to us that if an aircraft operates at hypersonic speeds of Mach 5 and higher, that it might be preferable to embed sensors that work closer to the speed of light than the speed of sound,” Goyne said.

UVA has several supersonic wind tunnels that can simulate engine conditions for a hypersonic vehicle traveling at five times the speed of sound.

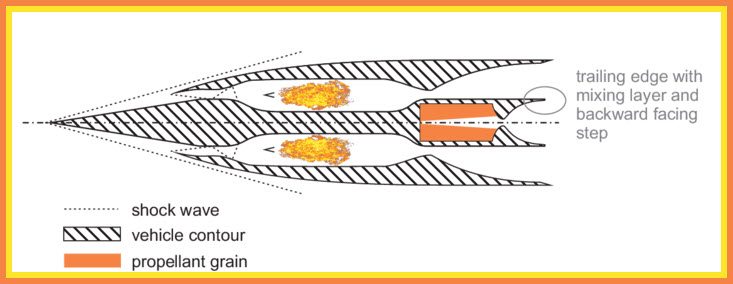

Goyne explained that “scramjets,” short for supersonic combustion ramjets, build on ramjet technology that has been in common use for years.

Currently, like ramjets, scramjet engines need a step-up to get them to a speed where they can intake enough oxygen to operate.

The latest innovation is a dual-mode scramjet combustor, which was the type of engine the UVA-led project tested. The dual engine starts in ramjet mode at lower Mach numbers, then shifts into receiving full supersonic airflow in the combustion chamber at speeds exceeding Mach 5.

No longer limited to information obtained at the engine’s walls, as pressure sensors are, the optical sensor can identify subtle changes both inside the engine and within the flow path.

The tool analyzes the AMOUNT OF LIGHT emitted by a source — in this case, the REACTING GASES WITHIN THE SCRAMJET COMBUSTOR — as well as other factors, such as the flame’s location and spectral content.

First proof of adaptive control

According to a release by the UVA, the wind tunnel demonstration showed that the engine control can be both predictive and adaptive, smoothly transitioning between scramjet and ramjet functioning.

The wind tunnel test, in fact, was the WORLD’S FIRST PROOF that adaptive control in these types of dual-function engines can be ACHIEVED WITH OPTICAL SENSORS, the release stated.

The team believes optical sensors may be a component of the future plane-like travel to space and back.

This could help in making an all-in-one aircraft that could glide back to Earth like the space shuttles once did.

“I think it’s possible, yeah,” Goyne said. “While the commercial space industry has been able to lower costs through some reusability, they haven’t yet captured the aircraft-like operations. Our findings could potentially build on the storied history of Hyper-X and make its space access safer than current rocket-based technology.”

Boom Supersonic reveals Overture aircraft and engine developments

2nd Aug 2024 | In News | By Michael Tyrrell

BOOM SUPERSONIC, the company building the world’s fastest airliner, has announced milestones across its Overture airliner and Symphony engine programmes.

Boom says it has REINVENTED THE COCKPIT with an all-new flight deck, designed around pilots with safety at the forefront. The company is making rapid progress on its Symphony engine, with hardware testing underway and the first full-scale engine core to be operational in just 18 months. Additionally, Boom has announced Symphony will be assembled in San Antonio, Texas through an expanded agreement with StandardAero.

These announcements come after the company conducted the historic first flight of its XB-1 supersonic demonstrator in March, and in June completed construction on the Overture Superfactory in Greensboro, North Carolina.

“Passengers and airlines are hungry for supersonic flight,” said Blake Scholl, founder and CEO of Boom Supersonic. “Following XB-1’s successful test flight, we’re accelerating. Overture features an all-new flight deck, incorporating extensive pilot feedback, resulting in a flying experience that is both innovative and instantly familiar. Our Symphony engine has quickly progressed through design into hardware rig testing, and with a fully operational engine core on track for next year, our rapid development approach is pacing ahead of schedule.”

Boom continues to partner with airlines and industry suppliers. Overture’s flight deck builds on the next-generation Honeywell Anthem avionics suite. An advanced head-worn vision system from Universal Avionics, who has joined the Overture program today, is integrated into the flight deck. Boom worked with BAE Systems to integrate Active Control Sidesticks into the Overture flight deck simulator displayed at the Farnborough International Airshow.

Overture’s flight deck builds upon years of learning in aviation safety and is the result of extensive feedback from airline, business, and military pilots. Incorporating the Honeywell Anthem avionics suite, Overture offers pilots more situational awareness and ease of control, providing passengers with the safest possible flight experience.

Boom’s flight deck offers pilots the benefits of advanced automation and envelope protection, together with a force-feedback system that allows pilots to feel how the airplane is flying. With key airplane features accessible through high-definition touch screens, Overture can benefit from ongoing over-the-air software upgrades. Overture flight deck capabilities include:

- Force-feedback sidesticks. For the first time on an airliner, force-feedback sidesticks allow pilots to control the plane while physically feeling both aircraft response and inputs made by the co-pilot or autopilot.

- Autoland and augmented reality. Building on the system flown on XB-1, Overture has an advanced augmented reality vision system for takeoff and landing, eliminating the need for the droop nose used on Concorde. Pilots can safely land using autoland or augmented reality views provided on a head-worn device and on the pilot’s primary flight display.

- Large 17-inch touchscreens. High-definition touchscreens eliminate the hundreds of breakers and buttons found in legacy cockpits. Every airplane function is accessible through software while physical controls—such as stick, throttle, and landing gear—are offered for safety-critical functions.

- Over-the-air upgrades. Overture will receive over-the-air software upgrades, meaning new features and improvements will arrive regularly. Airlines can control how upgrades are rolled out across fleets.

Boom recently completed a series of flight deck tests with commercial pilots from leading airlines, including Mike Bannister, former chief Concorde pilot for British Airways.

Boom revealed in June that it is already building and rig-testing Symphony hardware, starting with a full-scale test of combustor aerodynamics. THE FIRST 3D-PRINTED parts have been produced for Symphony, including fuel nozzles and turbine centre frames.

These hardware tests began just 18 months after the initial announcement of Symphony, demonstrating Boom’s rapid development approach. As part of this strategy, the company will conduct more than 30 engine hardware rig tests, allowing for validation and optimisation of all key engine components, ranging from fan and nozzle acoustics to combustor fuel efficiency.

Boom also announced that it has accelerated development of a full-scale engine core, which will be operational in late 2025. Engine core testing will analyse performance of the compressor, combustor, and turbine section. Data gathered will further refine engineering and expedite production of a fully certified engine. Following this rapid development approach, Boom expects to build and test multiple iterations before certifying the final refined engine.

Boom also expanded its existing MRO partnership with StandardAero to include the production of Symphony. StandardAero will assemble and test Symphony engines at its facility in San Antonio, Texas. The Symphony assembly line will scale to produce 330 engines annually within a footprint projected to total over 100,000 square feet of production space.

Additionally, Boom has announced it is teaming with aerospace leader ATI for advanced high-temperature materials and components for Symphony’s high pressure compressor integrated blade and disk stages and for its turbine assembly. These advanced nickel-based superalloys will enable Symphony to achieve high performance and reliability in sustained supersonic operation.

OVERTURE REMAINS ON TARGET TO ACHIEVE FAA AND EASA CERTIFICATION BY THE END OF THE DECADE.