Aeronautical Engineering Research makes major finds

in 1896, Bishop Wright reportedly expressed concern for his sons’ safety. He even delivered a sermon in Dayton declaring, “IF GOD HAD MEANT MAN TO FLY, HE WOULD HAVE GIVEN HIM WINGS”—a reflection of the era’s theological and cultural skepticism toward human flight. Such skepticism preceded the development of civil aviation technology but that doubt has persisted, witness these authoritative comments late in the 20th Century about the future development of man-made wings:

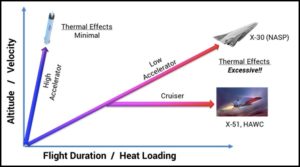

- Walter J. Boyne and R.E.G. Davies noted that while avionics and materials improved, the fundamental experience of flight—speed, altitude, and propulsion—had stagnated compared to the leaps of the early 20th century.

- NASA and Industry Analysts: Internal reports from NASA and Boeing in the 1990s acknowledged that without breakthroughs in propulsion (e.g., scramjets, antimatter), commercial aviation had reached a performance ceiling.

Research is what has extended the economic life of civil aviation , if not expanded its horizons on a vast basis. Proof of the utility in investing in development of new technologies is shown by the two reports from GE Aerospace attached below this introduction:

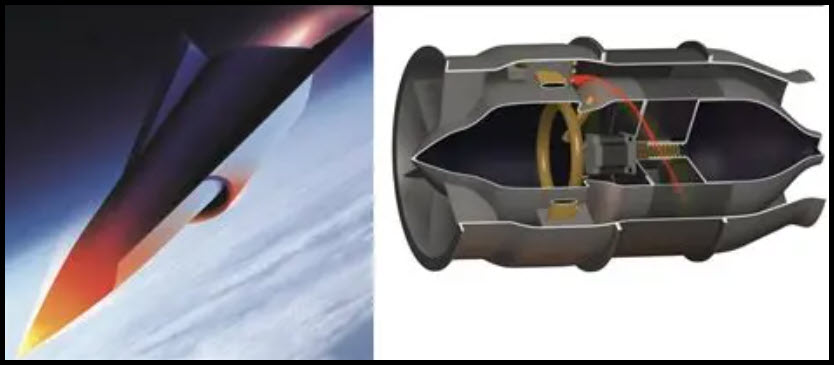

1.GE AEROSPACE announced that its engineers and scientists have achieved a MAJOR BREAKTHROUGH with the successful testing of its Atmospheric Test of Launched Airbreathing System (ATLAS) Flight Test Vehicle. Specifically-

- “Captive carry testing of reusable flight test hardware allows for more frequent testing in realistic atmospheric conditions to better understand system behavior.”

- The company also revealed successful demonstrations of two rotating detonation combustion (RDC) engines at its Aerospace Research Center in Niskayuna

- RDC tests demonstrated robust performance and showed a threefold increase in engine airflow compared to earlier hypersonic demonstrators.”

- The pace of this GE initiative is defined in this comment-

- “In just 10 months, our team advanced from its legacy ramjet to a 3X scale demonstrator with RDC. This rapid progress underscores the maturity of our technology and the strength of our roadmap toward integrated high-speed propulsion solutions.”

- Even deeper exploration into possible dramatic advances was announced by Oxford University and the US’s Brookhaven National Laboratory. A common solution to GREEN PROPULSION is the use of HYDROGEN as the energy source. Its supply, weight, combustibility and clean emission make it an attractive alternative. Not mentioned in the articles supporting the H2 alternative is the interaction of this gas with the MATEL CONTAINERS– weakening metals, causing unexpected cracks and failures. The Transatlantic team is using real-time 3D imaging to to track the behavior of internal defects in steel known as dislocations due to the presence of hydrogen. At this point, there are no sure answers, but the findings of this iteration should provide important knowledge to develop novel alloys specifically engineered to resist hydrogen embrittlement.

The pace of innovation has tested the FAA’s safety certification team and frustrated the entrepreneurs. The proprietary nature of such research makes it difficult for the career civil servants to assess the new ideas’ impact on aviation safety. JDA can help in such exchanges of critical information.

US firm tests air-breathing supersonic ramjet engine tech in milestone flight

Pentagon-backed ATLAS program aims to extend the range of future munitions with solid fuel ramjet propulsion.

GE Aerospace ran three successful supersonic ATLAS ramjet flights at Kennedy Space Center.

GE AEROSPACE announced on September 22 that it has completed supersonic captive carry flight tests of its Atmospheric Test of Launched Airbreathing System (ATLAS) Flight Test Vehicle.

The milestone took place at the Kennedy Space Center in Florida and marks an important step in advancing solid fuel ramjet (SFRJ) propulsion technology.

During the test campaign, the ATLAS system was carried on a Starfighter F-104 aircraft. According to the company, the system successfully reached supersonic speeds across three flights.

The company confirmed that the results validated the in-flight performance of solid fuel ramjets.

“This marks a pivotal moment for GE Aerospace as we showcase our solid fuel ramjet technology in flight for the first time,” said Mark Rettig, vice president & general manager of Edison Works Business & Technology Development at GE Aerospace.

“Captive carry testing of reusable flight test hardware allows for more frequent testing in realistic atmospheric conditions to better understand system behavior.”

Pentagon-funded development

The project is funded through Title III of the Defense Production Act, with support from the Pentagon. The goal is to scale up air-breathing propulsion technology to extend the range of future munitions.

The aviation firm said the data collected from the ATLAS program will be valuable for designing next-generation systems requiring higher speed, longer range, and better responsiveness.

The company is investing in multiple high-speed and hypersonic propulsion technologies as part of its broader defense strategy.

Expanding hypersonic portfolio

The aerospace giant has been expanding its capabilities in this field over the past few years. In 2022, the company acquired INNOVEERING, a firm specializing in hypersonic propulsion systems.

Earlier this year, GE also announced upgrades to its testing infrastructure at facilities in Ohio, New York, and Niskayuna. These improvements allow mission-relevant, higher-Mach testing at a scale that was not possible before.

Alongside the ATLAS announcement, the company revealed successful demonstrations of two rotating detonation combustion (RDC) engines at its Aerospace Research Center in Niskayuna. The tests involved a missile-scale ramjet and a dual-mode ramjet designed for high-speed aircraft.

Rotating detonation combustion advances

The RDC tests demonstrated robust performance and showed a threefold increase in engine airflow compared to earlier hypersonic demonstrators. “We’ve proven that GE Aerospace’s rotating detonation combustion designs are scalable,” said Rettig.

“In just 10 months, our team advanced from its legacy ramjet to a 3X scale demonstrator with RDC. This rapid progress underscores the maturity of our technology and the strength of our roadmap toward integrated high-speed propulsion solutions.”

RDC technology allows fuel and air to combust through detonation waves rather than conventional combustion methods. This enables higher thrust and efficiency while reducing engine size and weight. Testing began in July at the firm’s continuous flow propulsion facility.

The work was made possible through collaboration between GE Aerospace engineers, the acquired Innoveering team, and the company’s research center. These milestones build on GE’s 2024 achievement, when it took a dual-mode ramjet from concept to testing in less than a year.

GE Aerospace’s Edison Works division continues to drive innovation in defense propulsion and systems.

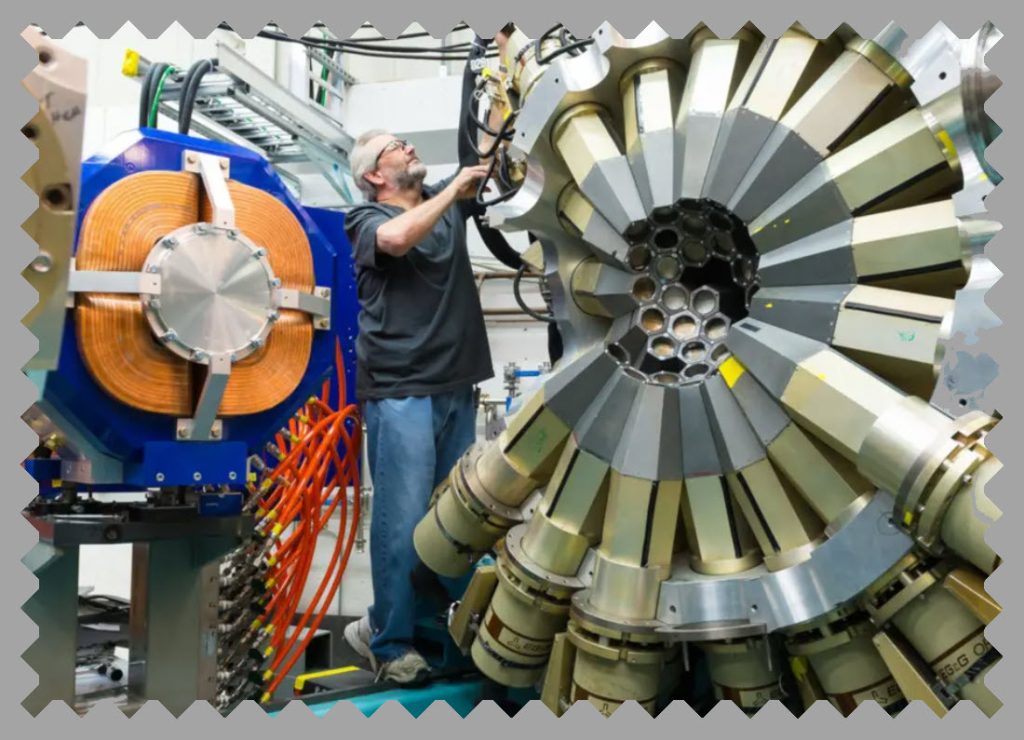

World-first steel experiment may advance nuclear fusion and hydrogen aircraft

Hydrogen weakens metals, causing unexpected cracks and failures

Nuclear particle accelerator at Argonne named ATLAS. Representative image.

Hydrogen is set to become a key energy source, fueling everything from aircraft and heavy-duty vehicles to cars and homes.

However, hydrogen comes with problems in weakening metals, causing unexpected cracks and failures.

In a world-first experiment, the University of Oxford and Brookhaven National Laboratory researchers have used real-time 3D imaging[1] to understand hydrogen’s effect on stainless steel.

The team studied in real-time how tiny defects inside stainless steel behave when exposed to hydrogen.

The findings could support the development of SAFER, MORE RELIABLE HYDROGEN FUEL SYSTEMS for applications like aircraft, fusion reactors, pipelines, and storage tanks.

“HYDROGEN has great potential as a clean energy carrier, but it’s notorious for making materials it comes in contact with more BRITTLE. For the first time, we have directly observed how hydrogen changes the way defects in STAINLESS STEEL BEHAVE DEEP INSIDE THE METAL, UNDER REALISTIC CONDITIONS,” said Dr. David Yang, lead researcher from the Brookhaven National Laboratory.

“HYDROGEN has great potential as a clean energy carrier, but it’s notorious for making materials it comes in contact with more BRITTLE. For the first time, we have directly observed how hydrogen changes the way defects in STAINLESS STEEL BEHAVE DEEP INSIDE THE METAL, UNDER REALISTIC CONDITIONS,” said Dr. David Yang, lead researcher from the Brookhaven National Laboratory.

“This knowledge is essential for designing alloys that are more resilient in extreme environments, including future hydrogen-powered aircraft and nuclear fusion plants,” Yang added.

Advanced X-ray imaging technique

Hydrogen is considered an ideal clean fuel for difficult-to-decarbonize sectors like shipping and aviation.

However, hydrogen embrittlement risks the integrity of metal components like high-pressure vessels and pipelines.

In a unique experiment, researchers used an ultra-bright X-ray beam at the Advanced Photon Source in the US to peer inside a speck of stainless steel (roughly 700 nanometres in diameter).

Using the Bragg Coherent Diffraction Imaging technique, they watched in real-time as hydrogen was introduced.

This allowed them to track the behavior of internal defects in steel known as dislocations due to the presence of hydrogen.

The team observed THREE CRITICAL CHANGES.

FIRSTLY, hydrogen made defects (dislocations) move and reshape more easily, acting like a “lubricant at the atomic level.”

SECONDLY, the team observed that the defects showed an unexpected upward movement (climb). It indicated that hydrogen allows for atomic rearrangements that are not typically possible at room temperature, making the metal less hard and more vulnerable.

AND FINALLY, as hydrogen accumulated, it reduced the stress around the defects—a process the team calls hydrogen elastic shielding. This essentially shields the metal from internal stress, weakening it from within.

Materials for hydrogen-based applications

The team stated that the unexpected failure of metals exposed to hydrogen is due to the gas allowing internal defects to move with greater ease and in new ways.

“Using coherent X-ray diffraction, a non-destructive method, we were able to watch atomic-scale events unfold in real time inside solid metal without cutting open the sample,” said Prof. Felix Hofmann, the study’s principal investigator from Oxford.

“Some of the results really surprised us by showing behaviour we weren’t expecting,” Hofmann added.

This research will help engineers model and predict materials’ performance in hydrogen-rich environments.

RECOMMENDED ARTICLES

The findings can be used to improve the multi-scale simulation frameworks that industries rely on to develop hydrogen-powered aircraft, vehicles, and infrastructure.

It also paves the way for developing novel alloys specifically engineered to resist hydrogen embrittlement.

The findings, which complement data from electron microscopy and simulations, will be used to develop models for the industry and to plan future experiments on how hydrogen affects other defects.

The study was published in the journal Advanced Materials.

[1] Real-time 3D imaging technology has seen significant advancements in 2025, impacting various fields such as neuroscience, healthcare, and manufacturing. Integrates advanced 3D imaging with AI to improve real-time anomaly detection in manufacturing processes, enhancing quality control and reducing defects. Perhaps this technology resembles this development:The Time-Resolved Brownian Tomography technique enables researchers to observe the dynamic atomic shifts in nanoparticles in real time. This method captures the movement of nanoparticles in a liquid environment, providing insights into their structural changes during chemical reactions. This advancement is particularly significant for developing new materials with tailored properties