More SAF feedstocks = cheaper green fuel?

Sustainable Aviation Fuels are but one of a number of possible solutions for aviation to reach its 2050 goal of Net Zero Carbon. This path has some hurdles to clear before it attains an acceptable or preferred status. The design of the powerplant to utilize SAF is still being developed, with some encouraging news. SAF offers the prospect of reducing/eliminating CONTRAILS.

Airline fuel is already a substantial percentage of their operational costs. The US points proudly of having increased its domestic production by 50%, an increase from around 2,000 barrels per day (b/d) to nearly 30,000 b/d in 2024. However, the immediate goal is at least 3 billion gallons of SAF annually by 2030.

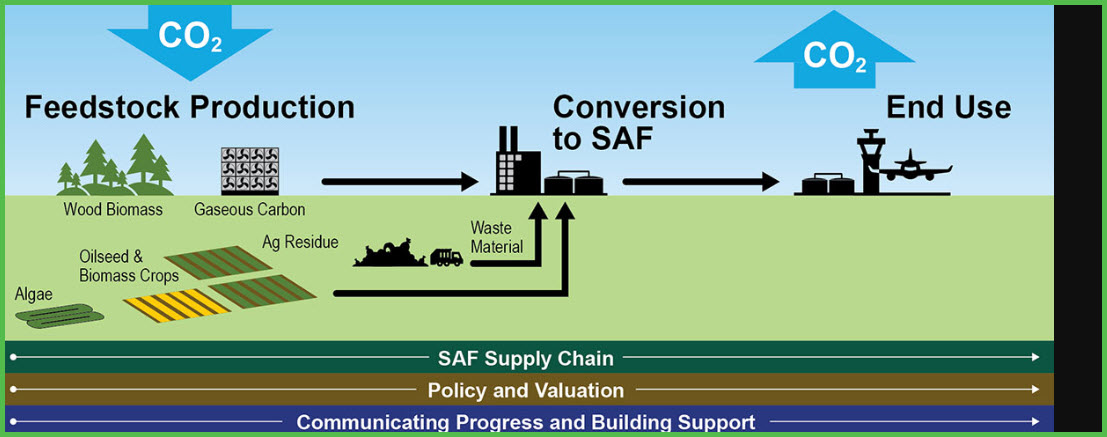

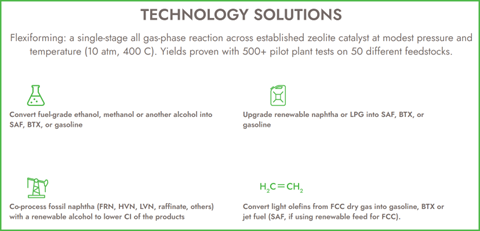

Cost of the feedstock and the cost of refining the raw materials into a ready to drop fuel make the buyers skeptical about this alternative. Below is an announcement by Universal Fuel Technologies that its FLEXIFORMING innovative process may help achieve those goals. UFT’s chemistry permits its refineries to use 50 different feedstocks including the byproducts from existing renewable fuel manufacturing processes. The company also believes that its process is energy efficient, using 75% less energy than existing ethanol-to-jet technologies, as well as 33% less hydrogen—i.e. greener and cheaper.

One caveat was mentioned—UFT has not yet received an ASTM approval. Use of GA unleaded fuel with STC approval and without ASTM recognition has caused quite a controversy. That likely will not be a problem for the Flexiforming request because UFT is a Member of the Advisory Committee of ASCENT (Center of Excellence for Alternative Jet Fuels and Environment), a cooperative aviation research organization co-led by Washington State University and the Massachusetts Institute of Technology. As such, the company is completely aware of the standards of the association/

New SAF Process Could Transform Industry

Flexiforming can use multiple feedstocks, even other SAF byproducts

By Curt Epstein • Senior Editor

August 14, 2024

UNIVERSAL FUEL TECHNOLOGIES (UFT) said its new sustainable aviation fuel (SAF) production pathway process could be an industry game-changer. The Los Altos, California-based company has developed FLEXIFORMING, a process that uses different feedstocks and even the byproducts from existing renewable fuel manufacturing processes to produce renewable fuels such as SAF.

According to the company, its process has been tested on more than 50 DIFFERENT FEEDSTOCKS, and it can also be integrated into existing SAF facilities, upgrading low-value byproducts into SAF and helping to drive down manufacturing costs. In addition, it claims that its flexiforming SAF—WHILE NOT TESTED TO ASTM STANDARDS—is drop-in ready.

“This technology allows SAF producers to create a genuinely drop-in-ready renewable jet fuel due to the presence of all required molecules,” said UFT CEO ALEXEI BELTYUKOV. “For example, a SAF producer using HEFA, which only produces paraffinic SAF, could add flexiforming to their plant to convert naphtha and LPG byproducts to aromatic SAF that can be blended with the HEFA SAF for a fully synthetic jet fuel that can be sold directly without the need for blending with conventional jet fuel.”

Beltyukov told AIN that the process is also energy efficient, using 75% less energy than existing ethanol-to-jet

technologies, as well as 33% less hydrogen. The company expects to submit its process to ASTM by year-end, along with the first commercial application.