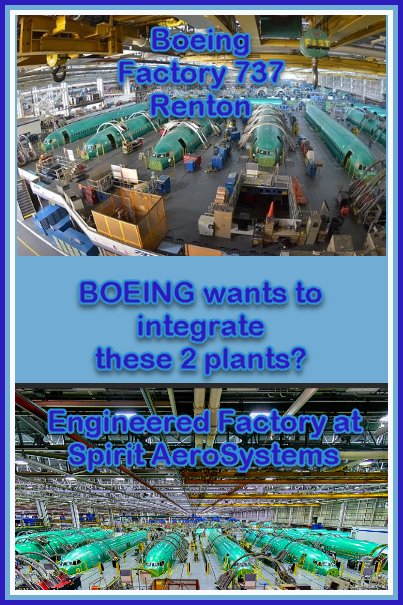

In the midst of a MESS, Boeing wants to add a source of the problem?

What will FAA do?

An FAA report pointed out significant problems in the Boeing Company’s SMS, QC, QA and other processes as well as its review of the products being delivered by Spirit AeroSystems. The criticisms are both extensive and not new.

A highly publicized deadline was set as 90 days by which Boeing must review and revise its critical and deficient safety system. That is no small task demanding focus of the Board, Senior Management, the safety team, all in the hangar and everyone in between.

Iterations of past SMS documents have not met the scrutiny of task forces, the NTSB, and the FAA. The most recent critique identified a real failure in establishing, communicating, and achieving a SAFETY CULTURE. Accomplishing this goal which must be the Company’s immediate #1 goal will demand significant attention by all in Arlington, Renton, Seattle, and Chicago(?).

Facing this paramount hurdle, what does Boeing announce that it wants to do? Acquire and integrate a Production Approval Holder (PAH), which has been cited as some of the past problem!!! So while it is fixing its own deficiencies, the OEM wants to try to integrate Spirit.

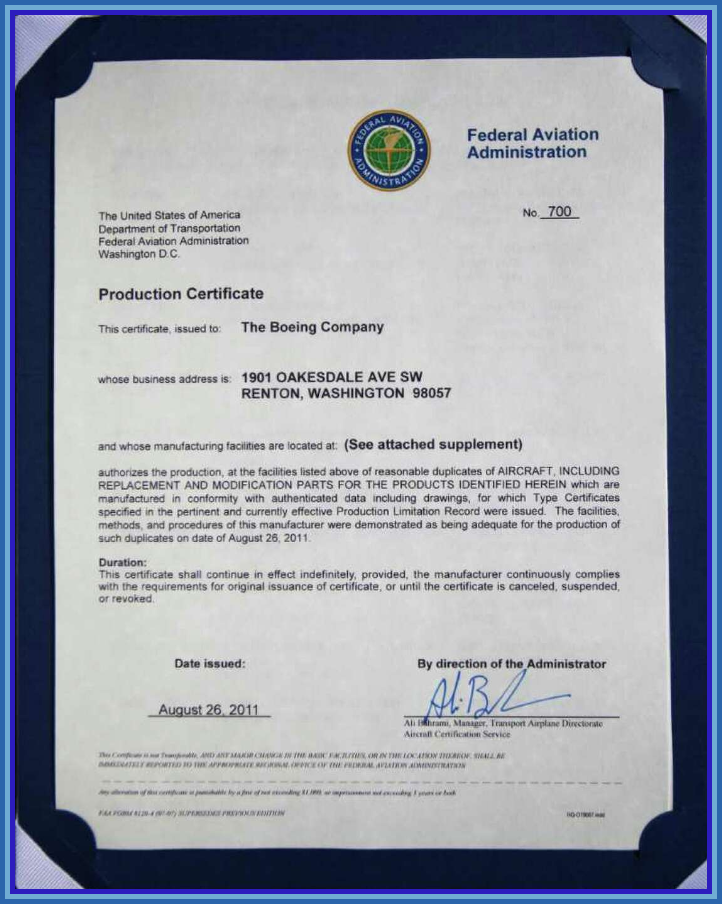

The standard FAA regulation and Advisory Circular say about such a transaction–

§ 21.144 Transferability.

The holder of a production certificate MAY NOT TRANSFER the production certificate.

AC No: 21-43A Subparts F, G, K, and O

6.7 Transferability. Sections 21.144, 21.314, and 21.614 state that a PAH MAY NOT TRANSFER THE PRODUCTION APPROVAL or letter of TSO design approval

6.7.1 The FAA prohibits that transfer of a production approval, but the FAA recognizes that companies do change ownership. In many cases, DESIGN DATA, QUALITY SYSTEMS, AND MANUFACTURING PROCESSES are all transferred as part of the change in ownership, and in these instances the FAA will support the establishment of a new production approval. 6.7.2 Applicants for new production approvals based on previously issued production approvals should consult their local ACO and MIO for assistance.

The details of this acquisition will be scrutinized by the FAA:

Who will manage Spirit if transfer permitted? Will such a new person improve on the recent past awful record?

What personnel will be in charge of the work on the floors? How will the FAA be satisfied that this new team is better?

Procedures, policies, manuals and everything that Spirit has been used will be under the FAA microscope and will have to meet what the inspectors believe are required NOW.

Resolving these problems will be required BEFORE the PAH approval is granted. The old Spirit safety systems had obvious deficiencies. Boeing’s current SMS system needs work. Not likely a quick approval.

Safety may not be the only issue; Spirit’s customers (and potential buyers?) likely will be concerned by Boeing’s proposal. For example:

Airbus A220

(formerly Bombardier C Series)-pylon for the Airbus A220 commercial jet (formerly Bombardier C Series). In addition to the pylon, systems, strut-to-wing hardware and the aft fairing package. The Belfast site is responsible for the design and manufacture of the advanced composite wings for the A220 family of aircraft including wing assembly and integration, and control surfaces. The site is also responsible for the manufacture of the Mid Fuselage.

Airbus A320—wing, leading and trailing edge. The components for these narrow-body jets are shipped to Airbus’ three A320 assembly lines in Toulouse, France; Mobile, Alabama; and Tianjin, China. New composite technology for the spoiler developed by Spirit will appear on the A320neo in mid-2019.

Airbus A350 XWB–central section panels are built in Kinston, North Carolina, then incorporated into the fuselage (Section 15) in Saint-Nazaire, France. Spirit also manufactures the A350 wing front spar and fixed leading edge.

Airbus A380-wing components (droop slats) for the A380 Superjumbo, the world’s largest passenger jet.

Boeing 737, Boeing 747-8, Boeing 767, Boeing 777 and 777X,Boeing 787

Rolls-Royce BR725–the nacelle package for the BR725 program and delivers a fully integrated powerplant system to Rolls-Royce.

Mitsubishi MRJ— designs and builds the pylon for the Mitsubishi Regional Jet (MRJ), a 70- to 90-seat-class aircraft.

Bombardier Challenger 350 business jet— center fuselage. The Casablanca site assembles emergency doors.

Bombardier Challenger 650 business jet

The Belfast site manufactures the center fuselage and engine nacelles.

Bombardier Global 5500 and 6500 business jets–forward fuselage, engine nacelles, horizontal stabilizer and other components.

Bombardier Global 7500 business jet-composite horizontal stabilizer which includes advanced composite skins.

If any or all of these Spirit customers object to its acquisition on a number of grounds. DELAY likely.

Boeing’s standing with the FAA has never been lower. The past trust placed by the Regulator has been fractured or destroyed. Posing to simultaneously meet its 90 day deadline and acquiring a PAH to increase its capacity and its control seems not to recognize the regulatory, discretionary action being demanded of the FAA.

Boeing Statement on Discussions with Spirit AeroSystems

March 1, 2024

ARLINGTON, Va., March 1, 2024 /PRNewswire/ — Boeing (NYSE: BA) today issued the following statement:

We have been working closely with Spirit AeroSystems and its leadership to strengthen the quality of the commercial airplanes that we build together. We confirm that our collaboration has resulted in preliminary discussions about making Spirit AeroSystems a part of Boeing again.

We believe that THE REINTEGRATION OF BOEING AND SPIRIT AEROSYSTEMS’ MANUFACTURING OPERATIONS WOULD FURTHER STRENGTHEN AVIATION SAFETY, IMPROVE QUALITY and serve the interests of our customers, employees, and shareholders.

Although there can be no assurance that we will be able to reach an agreement, we are committed to finding ways to continue to improve the safety and quality of the airplanes on which millions of people depend each and every day.