WHAT TO DO? GLOBAL AVIATION SUPPLY CHAIN ATTACKED

Recent reports have revealed that the aerospace global supply chain is at risk.

Most recently the New York Times article, F.A.A. Investigating How Questionable Titanium Got Into Boeing and Airbus Jets (below) revealed a new attack on the system’s integrity. The disturbing allegations point to titanium that were bought based on faked CERTIFICATES OF CONFORMITY and has caused great concern. Suspected Unapproved Parts have been a plague for decades; the FAA has devoted resources to blocking these counterfeits with some success. The Av Week article also relates the headache of AOG’s introduction of fake, safety critical parts into the global supply system should have heightened awareness among all of those in this chain.

The NYT article does not adequately track the path from the cradle of the titanium in question. It is not clear whether the QC personnel inspected the premises of the alleged source of the metal nor is there any mention of intake testing of the nonferrous material.

With reverse engineering, laser measurements, artificial intelligence and the sophisticated ability to reproduce the documents which have served as proof of airworthiness, good practice (PERHAPS NOT AN FAR REQUIREMENT) would have suggested that additional testing of the titanium from a new source (even if the paper (fake) showed an original source had a positive reputation) was warranted. The NYT report does state that the buyers have now tested the purchased materials.

Two days before the NYT article, AW&ST’s Senior Air Transport & Safety Editor, Sean Broderick reported that the AVIATION SUPPLY CHAIN INTEGRITY COALITION had completed the initial phase of its mission to prevent unairworthy items from entering the supply chain. Almost in anticipation of the Chinese bogus certificate, the leaders reported—

“things like document authentication and overall supplier standards and oversight.”

FIRST PHASE, which focused on research, wrapped up recently. It included reviews of current standards, guidance, and industry initiatives, such as the Aviation Suppliers Association’s ASA-100 voluntary distributor standards and audit program.

PHASE TWO will work to codify lessons learned into action items that industry can use to bolster current programs or introduce new ones.

Useful insights, but the Coalition’s Phase Two now has additional URGENCY.

++++++++++++++++

F.A.A. Investigating How Questionable Titanium Got Into Boeing and Airbus Jets

The material, which was purchased from a little-known Chinese company, was sold with falsified documents and used in parts that went into jets from both manufacturers.

Some recently manufactured BOEING AND AIRBUS jets have components made from TITANIUM that was sold using FAKE DOCUMENTATION verifying the material’s authenticity, according to a supplier for the plane makers, raising concerns about the structural integrity of those airliners.

The falsified documents are being investigated by Spirit AeroSystems, which supplies fuselages for Boeing and wings for Airbus, as well as the Federal Aviation Administration. The investigation comes after a parts supplier found small holes in the material from corrosion.

In a statement, the F.A.A. said it was investigating the scope of the problem and trying to determine the short- and long-term safety implications to planes that were made using the parts. It is unclear how many planes have parts made with the questionable material.

“BOEING REPORTED A VOLUNTARY DISCLOSURE TO THE F.A.A. regarding procurement of material through a distributor who may have falsified or provided incorrect records,” the statement said. “Boeing issued a bulletin outlining ways suppliers should remain alert to the potential of falsified records.”

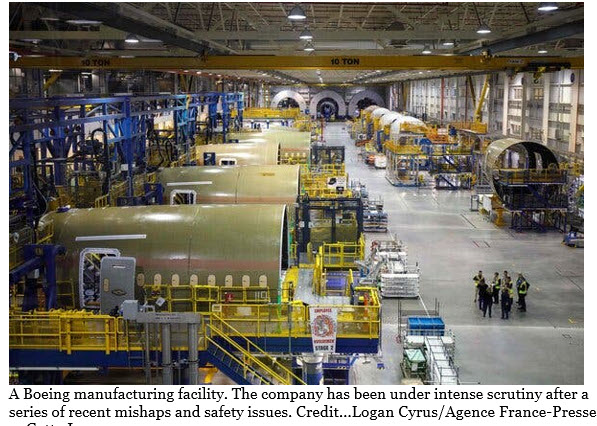

The revelation comes at a moment of intense scrutiny of Boeing and the broader aviation industry, which is reeling from a series of mishaps and safety issues. In January, a door panel blew off a Boeing 737 Max 9 jet while it was in flight, prompting several federal investigations. In April, Boeing told the F.A.A. about a separate episode involving potentially falsified inspection records related to the wings of 787 Dreamliner planes. Boeing reported to the F.A.A. that it might have skipped required inspections involving the jet’s wings and that it would need to reinspect some of the Dreamliners still in production.

On May 30, Boeing submitted a plan to the F.A.A. outlining safety improvements it planned to make and committed to weekly meetings with the agency. Dave Calhoun, the Boeing chief executive, is set to testify on Tuesday before a Senate panel on the company’s safety issues.

The use of potentially fake titanium, which has not been previously reported, threatens to extend the industry’s problems beyond Boeing to Airbus, its European competitor. The planes that included components made with the material were built between 2019 and 2023, among them some Boeing 737 Max and 787 Dreamliner airliners as well as Airbus A220 jets, according to three people familiar with the matter who spoke on the condition of anonymity because they were not authorized to speak publicly. It is not clear how many of those planes are in service or which airlines own them.

Spirit is trying to determine where the titanium came from, whether it meets proper standards despite its phony documentation, and whether the parts made from the material are structurally sound enough to hold up through the projected life spans of the jets, company officials said. Spirit said it was trying to determine the most efficient way to remove and replace the affected parts if that ended up being necessary.

“This is about documents that have been falsified, forged and counterfeited,” said Joe Buccino, a Spirit spokesman. “Once we realized the counterfeit titanium made its way into the supply chain, we immediately contained all suspected parts to determine the scope of the issues.”

The titanium in question has been used in a variety of aircraft parts, according to Spirit officials. For the 787 Dreamliner, that includes the passenger entry door, cargo doors and a component that connects the engines to the plane’s airframe. For the 737 Max and the A220, the affected parts include a heat shield that protects a component, which connects a jet’s engine to the frame, from extreme heat.

BOEING AND AIRBUS both said THEIR TESTS of affected materials so far had shown NO SIGNS OF PROBLEMS.

BOEING said it DIRECTLY purchased most of the titanium used in its plane production, so most of its supply was unaffected.

“This industrywide issue affects some shipments of titanium received by a limited set of suppliers, and tests performed to date have indicated that the correct titanium alloy was used,” Boeing said in a statement. “To ensure compliance, we are removing any affected parts on airplanes prior to delivery. Our analysis shows the in-service fleet can continue to fly safely.”

Airbus likewise maintained that “the A220’s airworthiness remains intact.”

“Numerous tests have been performed on parts coming from the same source of supply,” an Airbus spokeswoman said in a statement, adding, “The safety and quality of our aircraft are our most important priorities, and we are working in close collaboration with our supplier.”

The European Union Aviation Safety Agency said in a statement that they opened an investigation into the material after learning of the traceability issues from their counterparts in Italy. An agency spokesperson said the investigation is ongoing and has yet to turn up evidence of an immediate safety issue.

“However, the agency will investigate further the root cause of the document traceability issue and continues to monitor closely any new developments that could lead to a potential unsafe condition in the fleet,” the statement said.

Spirit has suffered from quality issues and financial troubles in recent years, and it came under new scrutiny this year after the episode in January involving the door panel of the 737 Max, whose fuselage it makes.

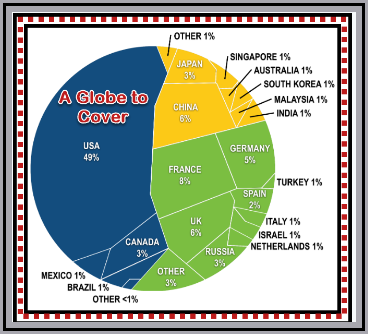

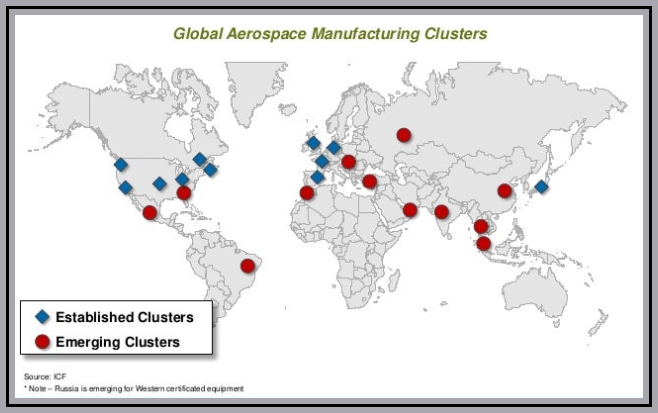

The problem illustrates the complex global supply chain used in producing modern jetliners, and the story of what appears to have gone wrong involves companies in China, Italy, Turkey and the United States.

The issue appears to date to 2019 when a Turkish material supplier, Turkish Aerospace Industries, purchased a batch of titanium from a supplier in China, according to the people familiar with the issue. The Turkish company then sold that titanium to several companies that make aircraft parts, and those parts made their way to Spirit, which used them in Boeing and Airbus planes.

In December 2023, an Italian company that bought the titanium from Turkish Aerospace Industries noticed that the material looked different from what the company typically received. The company, Titanium International Group, also found that the certificates that came with the titanium seemed inauthentic.

Turkish Aerospace Industries did not respond to a request for a comment.

Spirit began investigating the matter, and the company notified Boeing and Airbus in January that it could not verify the source of the titanium used to make certain parts. Titanium International Group told Spirit that when it bought the material in 2019, it had no clue that the paperwork had been forged, according to Spirit officials.

Francesca Conti, a general manager for Titanium International Group, said that the episode was under investigation and that she could not provide additional details. “We are cooperating with relevant authorities to address any issue eventually identified,” she said in an email.

The documents in question are known as CERTIFICATES OF CONFORMITY. They serve somewhat as a birth certificate for the titanium, detailing its quality, how it was made and where it came from, Spirit officials said.

People familiar with the situation said it appeared that an employee at the Chinese company that sold the titanium had forged the details on the certificates, writing that the material came from another Chinese company, BAOJI TITANIUM INDUSTRY[1], a firm that often supplies verified titanium. Baoji Titanium later confirmed that it had not supplied the titanium. The origin of the titanium remains unclear.

“Baoji Titanium doesn’t know about the company and has no business dealing with this company,” the firm said in a statement to The New York Times.

Without knowing where the material came from or how it was handled, it is impossible to verify the airworthiness of the parts, said Gregg Brown, the senior vice president for global quality at Spirit.

“OUR QUALITY MANAGEMENT PROCESS RELIES ON THE TRACEABILITY OF THE RAW MATERIALS ALL THE WAY FROM THE MILLS,” Mr. Brown said. “There has been a loss of traceability in that process and a documentation challenge.”

Spirit officials said they had STARTED TESTING TITANIUM PARTS TO MAKE SURE AVIATION-GRADE MATERIAL WAS USED. The company is testing components that are still in stock and that are on undelivered fuselages.

So far, Spirit’s testing has confirmed that the titanium is the appropriate grade for airplane manufacturers. But the company has been unable to confirm that the titanium was treated through the approved airplane manufacturing process. The material passed some of the materials testing performed on it but failed others.

Mr. Buccino, the Spirit spokesman, said the company was working with customers to identify the affected planes. Aircraft that are already in service will be monitored by airlines and removed from service earlier than normal if warranted, he said. More likely, he said, the affected parts will be removed during routine maintenance checks regardless of whether the titanium checks out.

Olivia Wang contributed reporting from Hong Kong. Kitty Bennett contributed research.

Mark Walker is an investigative reporter focused on transportation. He is based in Washington. More about Mark Walker

+++++++++++++++++++++

Parts Integrity Coalition Enters Final Phase

Sean Broderick June 12, 2024

WASHINGTON—A coalition working to develop BEST PRACTICES for PREVENTING UNAPPROVED PARTS from flying has moved into the recommendation-development phase and is on track to meet its self-imposed timeline of delivering a final report this year.

“We haven’t yet settled on specific actions, but we have a good sense of what we need to focus on,” coalition co-chair John Porcari told FAA/European Union Aviation Safety Agency (EASA) Safety Conference attendees June 11. “It includes THINGS LIKE DOCUMENT AUTHENTICATION AND OVERALL SUPPLIER STANDARDS AND OVERSIGHT. For each of these areas, we anticipate there will be actions that could be taken [immediately], others that are in the near term, and a final, long-term set.”

The AVIATION SUPPLY CHAIN INTEGRITY COALITION (ASCIC) was formed earlier in 2024 as a direct response to a records-falsification scandal that made headlines late last year. UK-based distributor AOG Technics sold thousands of engine parts with forged regulatory approval paperwork—8130-3s and European Union Aviation Safety Agency (EASA) Form 1s.

Parts allegedly sold as new by GE Aerospace and CFM for GE CF6 and CFM56 engines were found to have falsified records, and the companies determined they did not provide the parts to AOG Technics, as the distributor claimed. GE and Safran, its joint venture partner in CFM, spearheaded ASCIC’s formation. Other members are Airbus, American Airlines, Boeing, Delta Air Lines, StandardAero and United Airlines, though the coalition is getting input from many industry stakeholders.

Porcari said the group’s FIRST PHASE, which focused on research, wrapped up recently. It included reviews of current standards, guidance, and industry initiatives, such as the Aviation Suppliers Association’s ASA-100 voluntary distributor standards and audit program. PHASE TWO will work to codify lessons learned into action items that industry can use to bolster current programs or introduce new ones.

“We have been working with ASA and other organizations as part of this to better understand what works and what can be improved,” Porcari said. “What we do believe is that going forward, through basic DOCUMENT AUTHENTICATION EFFORTS, SUPPLIER STANDARDS AND PERHAPS PARTS TRACEABILITY, we will have more opportunities to protect against the use of unauthorized parts.”

[1] A search for Baoji Titanium resulted in a number of companies with the name variations.

+++++++++++++++++++