What EASA’s Airbus A321XLR’s Rear Central Tank tale tells about the TC process

The general public’s perception of what the FAA or any other national certification body (NCA) does may have been confused by a number of media reports. The below article about the European Union Safety Administration provides a more accurate picture of what the civil servants, around the globe, ACTUALLY do in fulfillment of their SAFETY Mission.

The process of seeking a TYPE CERTIFICATE (TC), the universal term for official determination of airworthiness, involves massive documentation. The NCAs define criteria[1] on which they will determine if the proposed design is safe. Then it is incumbent on the private company to test each of the points of emphasis by flying the aircraft and/or running equipment to create the data required by the NCAs.

These “airworthiness” assessments are rarely witnessed by a government examiner, but the numbers produced are heavily scrutinized by the NCA experts. After years of such testing, an iterative process in which the NCA request additional testing and/or analysis and the TC applicant complies with those requirements, plus a seemingly interminable schedule of meetings, the public body and the private entity decide whether or not to issue the final TYPE CERTIFICATE.

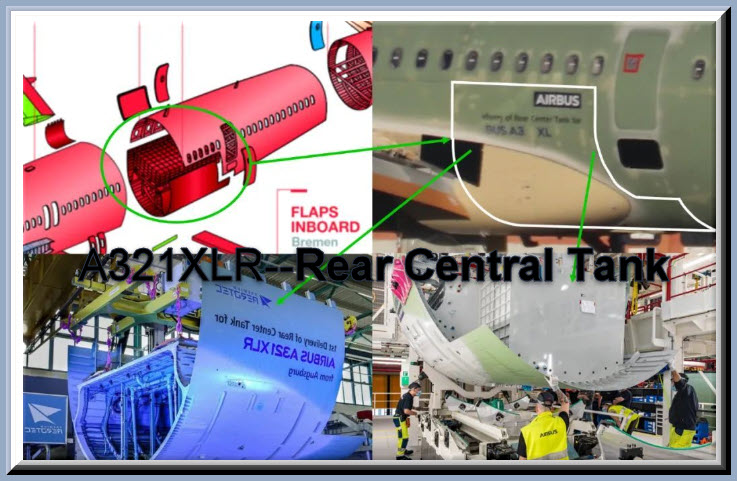

The illustrative EASA record of dealing with EUROPE’s OEM, AIRBUS, conforms these points. In fact, the certification of the Airbus A321XLR was delayed by the EU safety organization’s setting of SPECIAL CONDITIONS for theAirbus A321XLR’ s Rear Central Tank (RCT) EASA instructed Airbus add structures or systems or materials that would assure crash safety, fire safety and occupant protection. The Toulouse OEM proposed to improve the aircraft’s protection of the RCT witha more sophisticated design for the tank integration which made it more crash resistant, by introducing stronger material compositions and additional supporting structural provisions to protect the fuselage.

This represents the universally applied aircraft certification. The FAA “boots on the ground” are in their offices[2] looking over drawings and data with multiple meetings with other FAA offices and the TC applicants. The proposition that they are on the production lines would be useful in assuring safety is not realistic as a matter of time and expertise.

What this recitation should make it clear that type certification is a maze which can be best navigated by someone who knows what the next turn holds.

- Location: Toulouse, France.

- By FL360aero —

- The first A321XLR completed its maiden flight in June 2022, an extensive test programme involving three test aircraft followed to achieve the Type Certificate.

- Program is much delayed but more than 500 Airbus A321XLRs have been ordered to date.

- Entry into service was pushed back to 2024 from the original 2023 to address fuel tank issues raised by regulators.

- The A321XLR will offer an unprecedented range for a single-aisle aircraft of up to 8,700 km, with 30% lower fuel consumption per seat than previous generation aircraft.

Iberia must be happy as the EUROPEAN AVIATION SAFETY AGENCY (EASA) has approved the type certificate for the Airbus A321XLR, and the aircraft model can now enter service in Europe.

Following common practice, other regulators around the world will likely follow EASA’s lead and will soon approve the type certificates required for the operation of the A321XLR in other regions.

EASA and Airbus held over 400 joint meetings of technical experts, 900 flight test hours on three test aircraft, more than 500 certification documents were produced, reviewed and signed off, tests were witnessed, inspections carried out and audits completed.

The program is much delayed, but the Airbus A321XLR, powered by CFM LEAP-1A engines, has now received the Type Certificate from the EASA, that will allow the new aircraft to enter service at the end of summer. In its press release, Airbus said,

The award to Airbus of a Type Certificate for the A321XLR marks the end of a CERTIFICATION PROCESS for the European Union Aviation Safety Agency that LASTED MORE THAN FIVE YEARS. Airbus’s aim for the new model was to offer a narrowbody aircraft which has additional fuel capacity and so is suited to long-haul flights.

The aeronautical document was handed over by Florian Guillermet, Executive Director of EASA, to Isabelle Bloy, Chief Engineer of the A321XLR. Certification of the Pratt & Whitney-powered version is scheduled for late 2024.

- The A321XLR was officially launched at the Paris Air Show on 17 June 2019, with deliveries at that time expected from 2023.

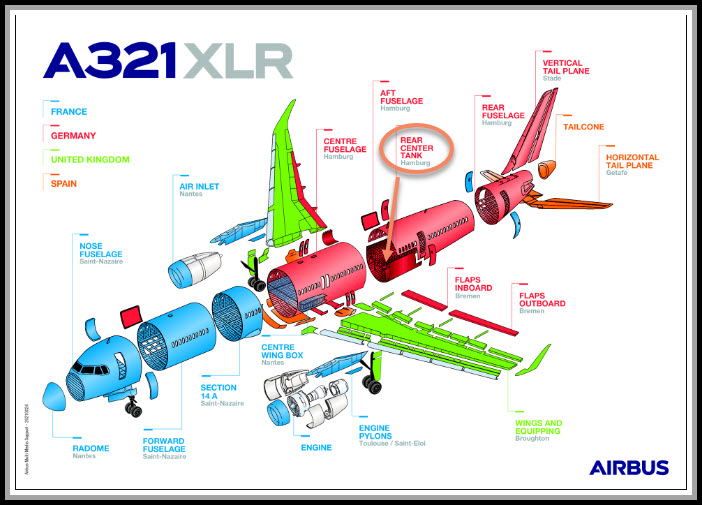

- Its design features a new permanent rear centre tank (RCT) for more fuel, strengthened landing gear for a 101 t (223,000 lb) MTOW, and an optimised wing trailing-edge flap to preserve take-off performance.

- The RCT will hold 12,900 L (3,400 US gal) of fuel, the equivalent of four 3,121 L (824 US gal) current Additional Centre Tanks (ACTs).

As per EASA, Airbus proposed to build in a new fuel tank, known as the Rear Central Tank or RCT. THE PROPOSAL WAS CLASSIFIED AS A MAJOR SIGNIFICANT CHANGE, BASED ON THE CLOSEST DERIVATIVE AIRCRAFT, THE A321NEO.

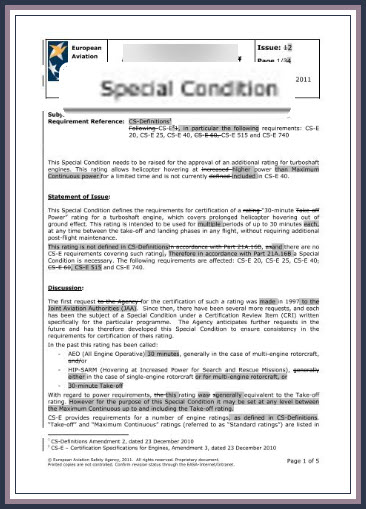

The RCT represented a novel unusual design, that was NOT FULLY COVERED BY THE EXISTING CS-25 CERTIFICATION SPECIFICATIONS, the main technical requirements that have to be complied with in the certification of large commercial aircraft.

EASA laid down SPECIAL CONDITIONS to address any gaps or inadequacies in CS-25. The special condition defines safety standards which any manufacturer wishing to adopt this type of change would have to meet to achieve certification approval, without prescribing exactly how they should achieve this.

A revised design with special conditions was approved by the United States Federal Aviation Administration in December 2022.

In this case, the safety challenge was posed by the addition of the new fuel tank, integrated within the fuselage, in the underbelly of the aircraft.

The special conditions set focused on crash safety, fire safety and occupant protection. For example, the risk of fire had to be mitigated to allow for a safe evacuation of passengers and crew in an accident.

EASA Executive Director Florian Guillermet, said :

“The aim of every action taken by EASA is to ensure that the aircraft is safe,” “OUR REQUIREMENTS CAN BE QUITE STRINGENT AND POSE SIGNIFICANT CHALLENGES TO THE MANUFACTURER, in this case Airbus. But we have a truly common aim of ensuring safety.”

Airbus responded by providing a sophisticated design for the tank integration which made it more crash resistant, by introducing STRONGER MATERIAL COMPOSITIONS AND ADDITIONAL SUPPORTING STRUCTURAL PROVISIONS TO PROTECT THE FUSELAGE for the case of an uncontrolled landing, and by introducing an inner liner to the tank to limit any potential leakage.

The changes to the aircraft went far beyond the RCT itself. The landing gear was reinforced and local structure changes made to accommodate the increased take-off weight resulting from the extra fuel carried. The fuel system was adapted to integrate the RCT. Some other product enhancements were made, for example to the flight controls.

Michael Singer, Head of Department – Large Aeroplanes at EASA, said :

“We needed to be sure that the design location of the tank would not in itself trigger a safety issue, that the tank was adequately robust and crash resistant, even in a case where the landing gear failed or an unknown threat such as an item on the runway could damage the tank, and finally we wanted proof that if the tank was compromised, the leakage rate would be limited so as not to pose a threat.”

The A321XLR is designed to be the longest-range variant of the A320 family. It is capable of flying non-stop routes of up to 8,700 kilometres, which is 1,300 kilometres more than the A321LR, which was previously the world’s longest-range single-aisle aircraft in service.

It is actually based on the A321LR, but it incorporates an extra fuel tank in the rear of the fuselage, which was the subject of special interest by the EASA , a more robust landing gear that allows it to weigh 101 tonnes on take-off – more fuel is needed – and redesigned flaps so that it has the same take-off performance as the A321neo.

[1] Historically these regulations have set PRESCRITIVE STANDARDS, specific numbers for all of the salient measures of airworthiness proof. Several years ago, the leading NCAs shifted to PERFORMANCE STANDARDS, which are established to demonstrate that a new or novel element of a TC request protects the public.

[2] Unionized workers in the FAA’s Flight Standards and Aircraft Certification organizations will be getting a $5,000 cash bonus and be allowed to continue spending only two days a week in the office.