Reading between the lines of the FAA’s and Boeing’s Safety/Quality meeting

Last week, the FAA and Boeing held a much publicized, 180-minute summit where the Washington/Chicago/Seattle company presented its” roadmap for continuous improvement. The 11 page “summary of its ‘PRODUCT SAFETY AND QUALITY PLAN’” was not released. All the public knows what Boeing has committed is found in quotes by the FAA Administrator, the Boeing CEO and the Boeing COO. Since these prepared statements are carefully vetted by lawyers and PR experts, it is unlikely that the words will reveal much in the way of substance. Consequently, what was said needs to be carefully parsed to identify any significance.

Below are the FAA’s Administrator’s remarks, a 2nd FAA press release, media quotes of Boeing’s CEO and COO comments and a 2022 Boeing Report on who its ACCOUNTABLE EXECUTIVE is as well as the responsibility of that position. Here is an effort to discern what the true meaning of this meeting was:

- No where did the FAA pronounce that Boeing had met the FAA’s May 30, 2024, to establish “a plan to fix quality problems and meet safety standards for building planes.”

- “…this plan does not mark the end of our increased oversight of Boeing and its suppliers, but the beginning of the next chapter. We will not approve production increases beyond the current cap until we’re satisfied.”

- “We will not approve production increases beyond the current cap until we’re satisfied.”

- “We need to see a strong and unwavering commitment to safety and quality that endures over time. This is about SYSTEMIC CHANGE, and there’s a lot of work to be done.”

- Boeing said its plan included “INCREASED INSPECTIONS and TIGHTER CONTROLS OVER SUPPLIERS” and “designed to improve employee training, simplify manufacturing” “eliminate defects at the source, and elevate our safety and quality culture.”[1]

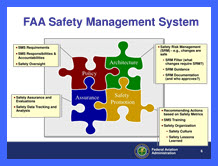

- WHEREAS the FAA listed its priorities as “First and foremost, Boeing is now required to have a mandatory SAFETY MANAGEMENT SYSTEM, which will ensure a structured, repeatable, systematic approach to identify hazards and manage risk.”

- A company that is truly committed to restoring a SAFETY CULTURE would have highlighted its corporate dedication to SMS in its summary of significant remedial actions.

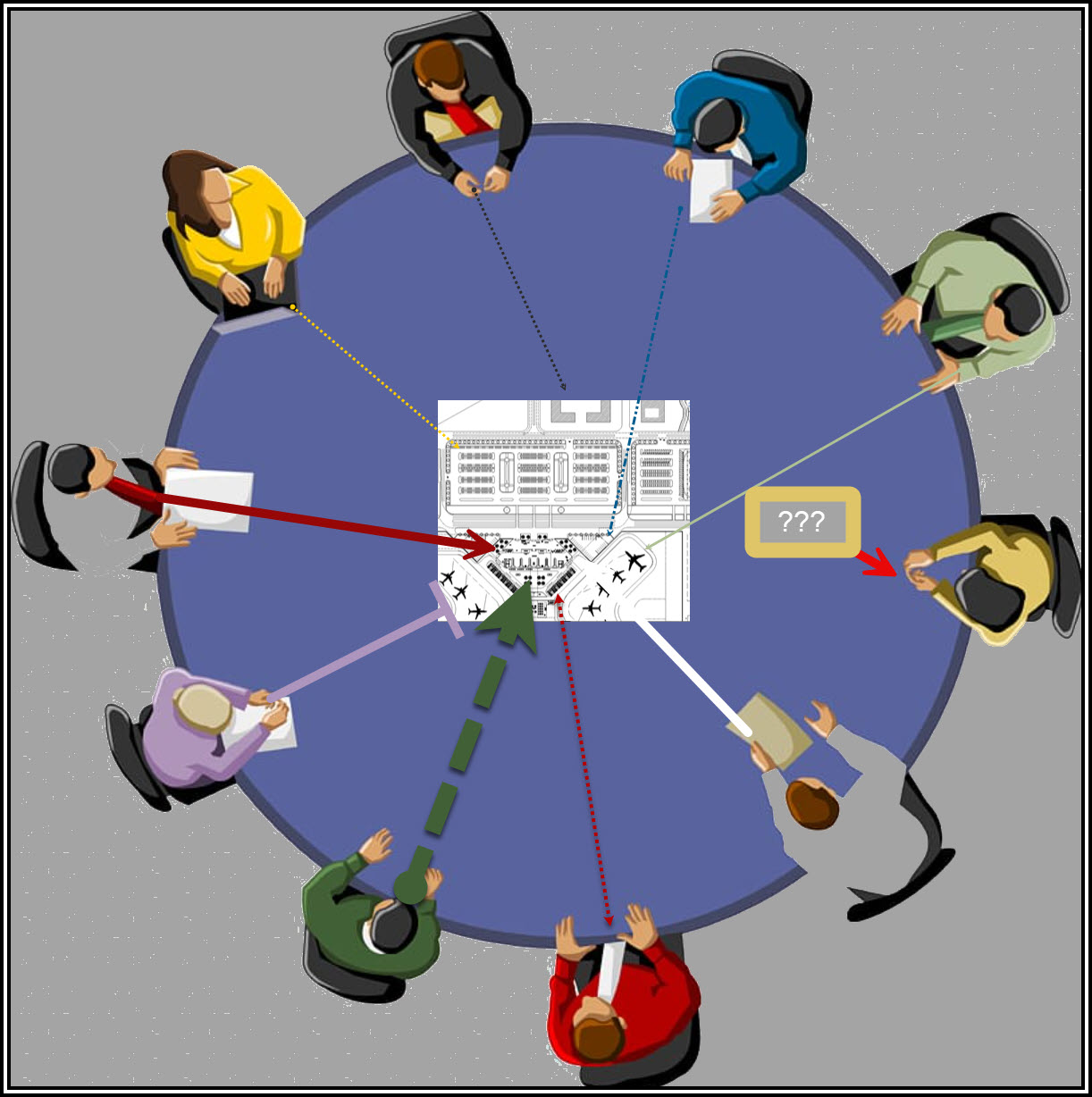

- Much of the recent press about the BCAC QC/QA focused on whistleblowers who claimed that their efforts to warn their superiors about problems were rebuffed or punished. CLEARLY, the hangar staff does not trust Boeing’s SMS process. The FAA rule (14 CFR Part 5) requires no retribution.

- A company that is truly committed to restoring a SAFETY CULTURE would have highlighted its corporate dedication to SMS in its summary of significant remedial actions.

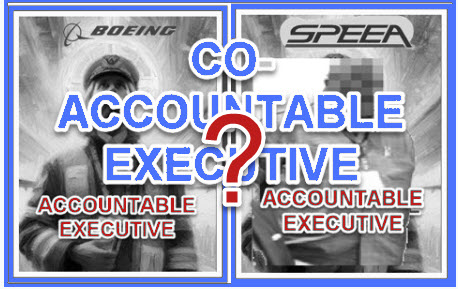

- The most critical aspect of SMS, based on the JDA team having set up more than a few of these programs, MUST START with the ACCOUNTABLE EXECUTIVE (AE). [The last section of this post quotes Boeing’s designation of its AE.] IT IS TELLING THAT BOEING DID NOT INDICATE THAT ITS AE was in ATTENDANCE, lead the PRODUCT SAFETY AND QUALITY PLAN.

This review should not be read to say that the aircrafts for which the FAA is issuing airworthiness certificates, are below standard. To the contrary, these planes are probably the most scrutinized of any airliner. The FAA wants to be sure that the procedures, policies and practices at Boeing are in place before the current limits are reviewed and MOST IMPORTANTLY, SMS is the foundation of everyone from workers to engineers to the QC/QA staff, the executives and the BOARD!!!

+++++++++++++++++

Press Conference on Boeing’s Roadmap for Continuous Improvement

FAA Administrator Whitaker’s comments:

“…Today, in response to our request in February, Boeing provided us their roadmap for continuous improvement. We just wrapped up a three-hour meeting to review it and talk about future implementation.

We underscored that they must follow through on implementing corrective actions and TRANSFORM THEIR SAFETY CULTURE. This is a guide for a new way for Boeing to do business. The FAA will make sure that Boeing makes lasting changes using all the tools at their disposal.

I made it clear to Boeing CEO, Dave Calhoun, and other senior leaders, that this plan does not mark the end of our increased oversight of Boeing and its suppliers, but the beginning of the next chapter.

We will not approve production increases beyond the current cap until we’re satisfied. Bottom line, we will continue to make sure every airplane that comes off the line is safe and reliable – regardless of how many planes Boeing builds.

We need to see a strong and unwavering commitment to safety and quality that endures over time. This is about SYSTEMIC CHANGE, and there’s a lot of work to be done. Our goal is to make sure that Boeing makes the necessary changes and has the right tools in place to sustain those changes.

Boeing has laid out their roadmap and now they need to execute. First and foremost, Boeing is now required to have a mandatory SAFETY MANAGEMENT SYSTEM, which will ensure a structured, repeatable, systematic approach to identify hazards and manage risk.

They have also committed to increasing employee training and communication; strengthening the anonymous reporting system that employees can use without fear of reprisal; boosting supplier oversight; making sure that things happen in the right sequence at every step of production; and getting more input from users of the system, including pilots.

The FAA will provide oversight at every step of the way in this process. We certify every 737 Max before it can be put into service, and we will continue to do so.

We will also provide enhanced oversight of Boeing and its suppliers. Practically speaking, this means more safety inspectors in the Boeing and Spirit facilities; more feedback from company employees to gauge the effectiveness of change; additional inspections at critical points of the production process; and monitoring metrics to identify areas of concern.

Safety is a team sport; everyone has a role to play. Boeing must do their part, and we will be there to make sure they do that. Appreciate you being here today, and I’m happy to take some questions.

+++++++++++++++++++++++

FAA Continues to Hold Boeing Accountable for Implementing Safety and Production Quality Fixes

The agency required Boeing to provide a detailed update on completed actions as well as mid- and long-term actions Boeing will take. These actions include:

- Strengthening its Safety Management System, including employee safety reporting

- Simplifying processes and procedures and clarifying work instructions

- Enhanced supplier oversight

- Enhanced employee training and communication

- Increased internal audits of production system

Additionally, Boeing had to identify the results of completed actions and how it will monitor those and future actions to validate progress and sustain the changes.

To ensure long-term success, the FAA will actively monitor review Boeing’s progress in a variety of ways, including:

- A team of FAA subject matter experts will continually review Boeing’s progress and the effectiveness of the changes in addressing the audit findings and expert panel recommendations

- Senior FAA leaders will meet with Boeing weekly to review their performance metrics, progress, and any challenges they’re facing in implementing the changes

- They also will conduct monthly reviews to gauge Boeing’s progress

The FAA will continue its enhanced oversight of Boeing and its suppliers. This includes:

- More safety inspectors in the Boeing and Spirit AeroSystems facilities

- More conversations with company employees to gauge the effectiveness of changes

- Additional inspections at critical points of the production process and auditing of the production process

- Monitoring quality system metrics to identify any areas of concern

…”

+++++++++++++++

Boeing tells federal regulators how it plans to fix aircraft safety and quality problems

Boeing released an 11-PAGE summary of its “PRODUCT SAFETY AND QUALITY PLAN,” which described steps the company is taking, including INCREASED INSPECTIONS and TIGHTER CONTROLS OVER SUPPLIERS. It also says how Boeing will measure its improvement.

CEO David Calhoun, who announced after the Jan. 5 blowout during an Alaska Airlines flight that he would step down at the end of the year, said the document was crafted from comments by EMPLOYEES, the FAA, AIRLINES and INDEPENDENT EXPERTS.

“Many of these actions are underway, and our team is committed to executing on each element of the plan,” Calhoun said in a statement. “It is through this CONTINUOUS LEARNING and IMPROVEMENT PROCESS that our industry has made commercial aviation the safest mode of transportation. The actions we are taking today will further strengthen that foundation.”

Stephanie Pope, a possible successor to Calhoun who was recently promoted to chief operating officer and chief executive of Boeing’s commercial airplanes division, said the plan was designed to improve employee training, simplify manufacturing, “eliminate defects at the source, and elevate our safety and quality culture.”

++++++++++++++

“Boeing’s Accountable Executive is the Chief Executive Officer (CEO) of the company. The CEO retains the ultimate responsibility, authority, and accountability for the safety performance of Boeing. In the context of safety management, the CEO serves as the SMS Accountable Executive, ensuring that safety practices and culture are prioritized across the organization.

++++++++++++++++++

By designating a UNION LEADER to be CO-ACCOUNATBLE EXECUTIVE might not that “participation in SMS assure that the union trusts and participates in this CRITICAL RISK MANAGEMENT process???

++++++++++++++++++++++

[1] These insights came primarily from the new COO whose background is finance and accounting.