GREAT GREEN NEWS: Pittsburgh brings SAF production on airport

The Allegheny County Airport Authority’s (ACAA) Pittsburgh International Airport (PIT) has initiated another significant step as a leader in GREEN Technology at airports. Their most recent achievement involves the addition of a Sustainable Aviation Fuel (SAF) at the existing fuel farm. This is one of a series of similarly environmental advances, such as:

- Microgrid Innovation: In 2021, PIT became the first airport in the world to be powered entirely by its own on-site microgrid, fueled by natural gas and solar energy. This ensures energy resilience and reduces dependence on the regional grid. The microgrid enables Pittsburgh Airport to be energy self-sufficient, a status that looked especially significant this spring, when power grid failures shut down London Heathrow and, in a separate incident, caused widespread flight disruptions at airports in Portugal and Spain.

- LEED Gold Terminal: A new terminal, opening in 2025, is designed to meet LEED Gold Certification standards, emphasizing energy efficiency, sustainable materials, and reduced emissions.

- Land Use for Innovation: PIT is leveraging its 8,800 acres not just for aviation, but for research, energy development, and sustainability pilots, in collaboration with institutions like Carnegie Mellon University.

In an interview with PIT’s CEO CHRISTINA CASSOTIS, said:

“The aviation industry has set a big goal to decarbonize by 2050. That work starts here in Pittsburgh.” Her leadership has turned PIT into a national model of innovation, blending operational excellence with environmental stewardship.

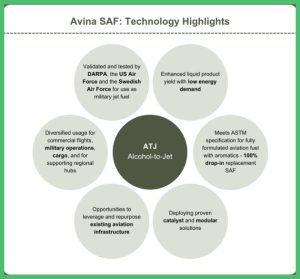

She is spearheading the development of the first on-airport Sustainable Aviation Fuel (SAF) production facility in the U.S., in partnership with Avina. This project aims to disrupt the global SAF supply chain by producing fuel locally, rather than importing it from places like Singapore. The Alcohol-to-jet (ATJ) process using PureSAF™ technology developed by Swedish Biofuels AB and licensed by KBR. This innovative facility generates some impressive impacts in aviation and Western Pennsylvania;

- Production Capacity: Over 100 million gallons of SAF annually, with at least 70 million gallons available for use at PIT

- Carbon Impact: SAF produced will have a carbon intensity at least 65% lower than conventional jet fuel

- Timeline: Construction is expected to begin soon, with operations projected to start by 2027

- Job Creation: Hundreds of full-time jobs expected during and after construction

- Regional Supply Chain: SAF will also be piped and shipped to airports across the Northeast, Midwest, and Canada

- Energy Resilience: Builds on PIT’s existing clean energy microgrid, making it a leader in airport sustainability.

- aviation infrastructure

Ms. Cassotis emphasized that this project builds on the airport’s reputation for energy innovation, including its on-site microgrid powered by solar and natural gas. The SAF facility will further position PIT as a global leader in sustainable aviation infrastructure.

She was named in 2024 as the Pittsburgher of the Year by the magazine of that name. The article announcing that honor provides insights into her background:

“…She told Pittsburghers the hub was not coming back. The airport — which opened in 1992 as the largest hub for US Airways, its dominant airline at the time — no longer fit that model. The financially troubled airline pulled out of the hub in 2004, leaving the airport authority saddled with debt and empty gates. It no longer was a place where a large percentage of travelers changed planes; it was now an origin-destination airport…

…And she has innovated. Pittsburgh International became the first major airport in the world to run on its own natural gas and solar energy microgrid. Even in the midst of the pandemic, she forged ahead with a new $1.57 billion landside terminal, funded without any taxpayer money and scheduled to open later in 2025. The ultimate outsider, she shook things up.

Great initiative by Pittsburgh and Ms. Cassotis. A city with a lengthy pollution history is now in front of the Airports Green Movement.

Pittsburgh Airport to Host First On-Site SAF Production Facility in US

Pittsburgh International Airport is set to host the first on-site SAF production facility in the US, developed in partnership with AVINA. Using alcohol-to-jet technology, the plant will produce over 100 million gallons annually, reduce emissions by 65%, and create local jobs. This project supports the aviation sector’s transition towards decarbonisation.

Pittsburgh International Airport (PIT) will become the first US airport with an on-airport sustainable aviation fuel (SAF) production plant. The development project is undertaken in partnership with AVINA SYNTHETIC AVIATION FUEL (Avina), a company dedicated to clean and cost-effective fuel solutions. The project is a significant milestone in the decarbonisation and energy independence process of aviation.

The plant will utilize an alcohol-to-jet (ATJ) process, a technology that transforms sustainable alcohol into jet fuel. The PureSAF™ technology applied in the process was created by Swedish Biofuels AB and is licensed worldwide by KBR. It’s engineered to provide the rigorous performance requirements of aviation fuels with much lower carbon emissions. SAF produced through such a process can lower lifecycle greenhouse gas emissions by at least 65% compared to traditional fossil-based jet fuels.

The facility will be within PIT’s land, south of its main terminal. This position is likely to enhance the employment of SAF by airports’ users, with proximity increasing its affordability and ease of access. Having the plant on site is also likely to reduce transportation as well as delivery costs, which have historically served as impediments to its large-scale usage.

The plant will be developed in stages, and by its completion, the plant will be able to manufacture more than 100 million gallons of SAF each year. This is a huge boost in US domestic SAF capacity, as well as the overall availability of clean aviation fuel in America. The project will also establish hundreds of permanent jobs, boosting the local economy in the Pittsburgh area.

Global demand for sustainable aviation fuel is increasing on account of regulatory stimulus, corporate emissions pledges, and keeping pace with international decarbonisation targets. IATA and numerous industry organizations have long pinpointed SAF as the key enabler of net-zero aviation by 2050. However, production has been expensive and supply limited, to maintain at bay widespread adoption thus far.

Pittsburgh’s new SAF plant circumvents these problems with local manufacture and the use of cutting-edge technology to minimize cost. Alcohol utilized in the ATJ process will be manufactured from renewable materials, further promoting the circular economy and sustainable supply chain.

MAJOR INDUSTRY PLAYERS, SUCH AS AIRCRAFT MAKERS AND SAF SUPPLY CHAIN PARTNERS, HAVE ENDORSED THE INITIATIVE. The PIT project is a trailblazer for other America regional airports, which would provide a blueprint for future installations of SAF facilities across America.

As pressure on aviation emissions worldwide continues to be fierce, developments like the Pittsburgh SAF facility are helping to usher in a cleaner future for the skies. The US SAF market is set to increase dramatically over the coming decade as policy like the Inflation Reduction Act, as well as thousands of state incentives, create the supporting conditions for growth.

PIT’s agreement with Avina is also an example of the way that public-private collaboration can speed the installation of clean fuel. Though the main purpose is to supply the airport and airline partners, the center will also supply SAF to other surrounding aviation centers, spreading its environmental benefits.

The financial effects of the project spill over into other sectors. The investment in SAF manufacturing capacity production is diversifying the energy mix and opening up new clean tech job opportunities. Engineering, maintenance, logistics, and fuel technology jobs will be created in construction and operating phases.

As air transport emits about 2-3% of CO₂ emissions, the innovation of on-site SAF production units is vital to mitigating the industry’s carbon footprint. Other alternative powertrains such as electric or hydrogen-powered planes are still under development, but SAF provides an immediate and scalable reduction of emissions by utilizing existing aircraft engines and infrastructure.

The Pittsburgh effort also positions the evolving airport role to sustainability in the spotlight. Airports are becoming more engaged in multi-role capabilities beyond the simple movement of passengers, with renewable energy, smart infrastructure, and green fuel technology being integrated into operations. With this potential for SAF, PIT becomes part of a growing number of airports globally looking to shape the aviation value chain through on-airport sustainability efforts.

While work on the facility continues, aviation and energy sector stakeholders will be holding their breaths to see its success. If it works, it would set the stage for other airport facilities throughout the country, a series of decentralized SAF manufacturing plants to be constructed to change fuel supply chains and bring energy resilience.