Boeing’s Vision of Wireless Power transfer- apply to your aircraft?

An obscure PressWire posting mentions BOEING’s $10.3 million (CD) investment in Solace Power, a company specializing in wireless power technology, specifically—

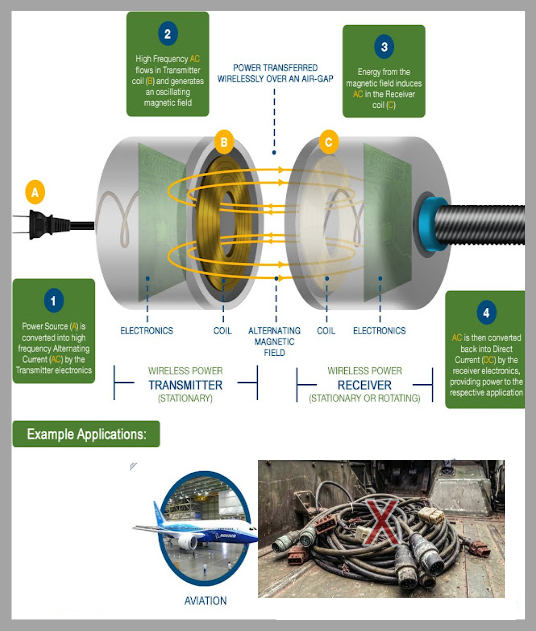

“Rather than using a wire harness to bridge power from A to B, [Solace] can design custom wireless power transmitters and receivers. You’ll still get the power across, but you will eliminate the connection point.

Wireless can eliminate connection points resulting in a point of failure; reduces manufacturing time and operational downtime risk and creates fully removable components without safety risks

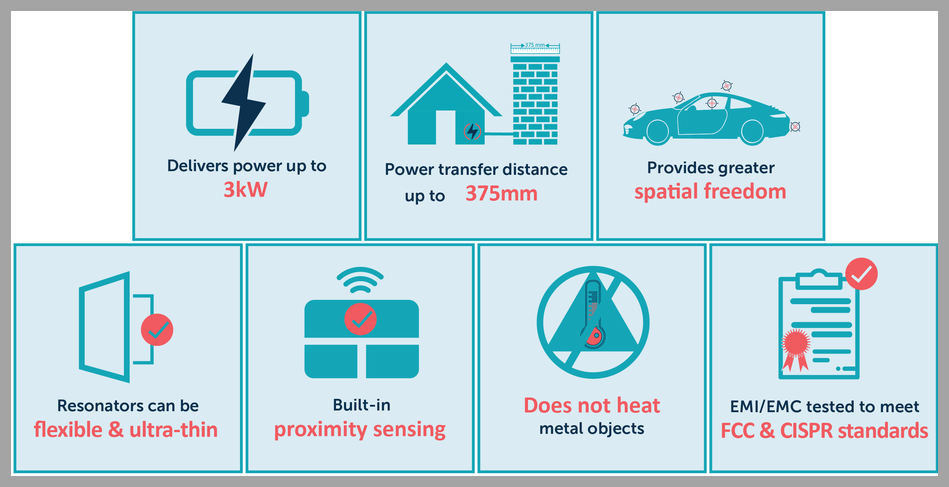

In designing your aircraft’s electrical system- transmitters and receiver modules can be designed to fit available space; transfer distance can be as little as a few mm, up to several CMS; can be designed to avoid heating of nearby metal; and the Solace hardware is fully tested to EMI and safety standards.”

Solace Power’s wireless power and data-transfer technology has direct aviation applications, and Boeing’s repeated investments strongly indicate that these aerospace uses are the primary driver. WHY?

-

-

- Modern wide‑body jets contain ~100,000 individual wires.

- When bundled with harnesses, clamps, and supports, the total mass reaches ≈7,400 kg (≈16,300 lb) for a typical wide‑body.

- Aerospace America analysis notes that a wide‑body’s wiring and harnesses “would tip to nearly 7,400 kilograms,” which is about 3% of the aircraft’s weight.

-

How will wireless power transfer improve aircraft SAFETY, EFFICIENCY and ENVIRONMENTAL status:

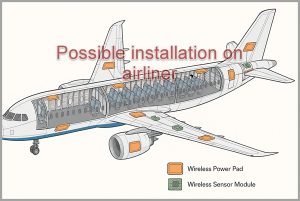

- Reduce wiring complexity inside aircraft

- IMPROVE RELIABILITY by eliminating connectors (a major failure point)

- Enable new sensor placements in hard‑to‑reach or moving components

- Support modular avionics architectures

- Reduce maintenance burdens

Boeing’s strategic investment in this new power transmission systems will translate into real design improvements for its future traditional aircraft.

Boeing’s venture, Wisk Aero, an AAM for which weight is a significant design consideration, likely will advantage from the use of SOLACE’s systems. Wisk’s distributed, tilt‑prop eVTOL is exactly the kind of platform where wireless at moving interfaces (booms, tilting props, control surfaces) will improve its operational capabilities and design weight. The application of their systems will make the Wisk Aero in these dimensions:

- Moving joints and tilt mechanisms need power and data routed through them.

- Today that usually means flexible cables, slip rings, connectors, and complex harness routing along each boom.

- Those are high‑vibration, high‑cycle, high‑maintenance

- Eliminate or reduce slip rings and flex harnesses in the tilt‑prop joints.

- Place wireless power pads in the fixed wing/boom structure and receivers in the tilting nacelle or prop module.

- Use wireless data links (WAIC‑class) for local sensors (position, temperature, vibration, motor health) instead of running bundles through the hinge.

- Reduce connector count, chafe risk, and water‑ingress issues in exposed booms.

- Lower maintenance on the most mechanically stressed parts of the aircraft.

- Weight savings from shorter harness runs and fewer protective conduits.

- Simpler modular replacement of tilt‑prop assemblies (swap the module, not the harness).

Innovation provides a source for new jobs and challenges. This disruptive change will impact:

- Over 37,000 U.S. aerospace jobs currently involve aircraft wiring installation and maintenance, spanning roles in manufacturing, design engineering, and field support.

- Retraining and reeducating these skilled workers can be accomplished through the transition from old to new.

- The FAA staff, certification and maintenance, will need similar adjustments—NB the certification staff will have to have their upgrading front end loaded.

- In this period of so many new forms of aviation (UAS, eVTOL [urban and beyond], space and beyond), all in the design phase of their new aircraft should consider both the applicability of this extraordinarily useful hardware AND the airworthiness tests that the FAA is likely to apply (GOOD SOURCE FOR SUCH INSIGHTS).

Why Boeing invested $10.3 Million in wireless power company Solace Power

Aircraft manufacturer Boeing has announced a $10.3 million investment in Solace Power, a company specializing in wireless power technology.”

Aircraft manufacturer Boeing has announced a $10.3 million investment in Solace Power, a company specializing in wireless power technology.

“This represents an opportunity for Boeing to invest in a company operating in a new and emerging space that could radically change the world of wireless power,” said Kagan.

Solace Power Inc. develops and manufactures wireless power solutions for a wide range of applications across multiple industries.

“Solace Power has said it plans to open a new production facility, which I understand could double its workforce during 2026,” Kagan said. “That is the kind of growth I continue to expect from the company as it expands into additional industries and sectors.”

Solace Power has developed core technology applicable across multiple market verticals, including automotive and telecommunications.

“This positions Solace Power to continue expanding into new markets, both within and beyond automotive and telecommunications,” Kagan said.

“Solace Power is a global leader in wireless power technology,” he added. “Boeing’s investment underscores the value and potential of Solace Power’s technology.”