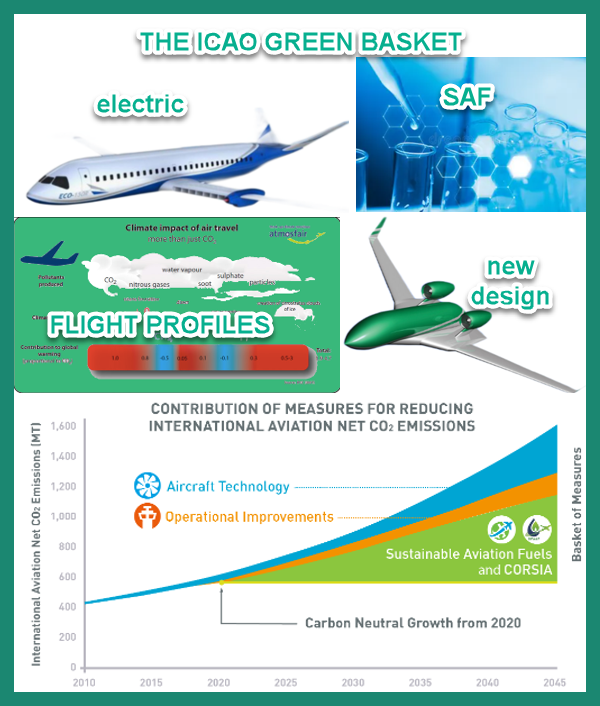

What’s in Aviation’s GREEN BASKET?

Below are two fascinating articles about efforts to fill the green basket of tools to reach a daunting challenge for NET ZERO CARBON EMMISSIONS by 2050. The first explains how bacteria PSEUDOMONAS PUTIDA may provide a path to this goal. The second paper explores HOW DISTRIBUTED ELECTRIC PROPULSION (DEP)[1] may be an answer. The information is too technically complex to try to summarize.

Global Aviation has imposed on its industry a challenging green goal. An environmental standard was a result of ICAO’s usual process for formulating general policies, developing, and updating specific Standards and Recommended Practices (SARPs). Through years of that intraorganizational effort, ICAO set a goal for aircraft emissions. Its Committee on Aviation and Environmental Protection (CAEP) with adoption by set the ICAO Assembly at its 41st Session in 2022 by its Resolution A41-21 Consolidated statement of continuing ICAO policies and practices related to environmental protection — Climate change.

The aviation community of the world established that collective long-term global aspirational goal for international aviation (LTAG) of NET-ZERO CARBON EMISSIONS BY 2050, in support of the Paris Agreement’s temperature goal. To achieve the global aspirational goals and to promote sustainable growth of international aviation, ICAO is pursuing a basket of measures including aircraft technology improvements, operational improvements, sustainable aviation fuels, and market-based measures (CORSIA).

This information below elucidates the potential of these research efforts in two disparate fields of science and engineering.

+++++++++++++++

Researchers optimize bacteria for isoprenol production as SAF precursor

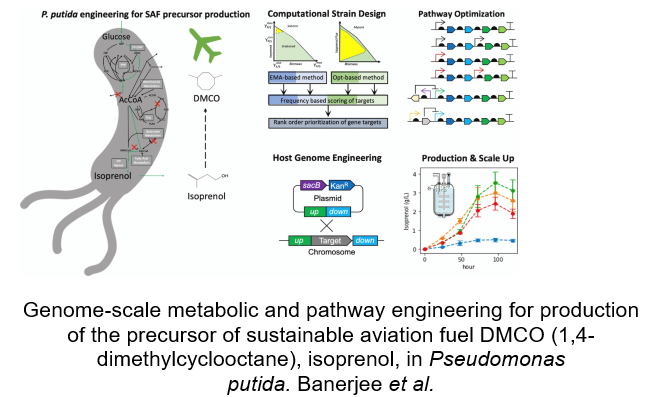

Researchers from the Joint BioEnergy Institute have used advanced computing tools to engineer the bacteria PSEUDOMONAS PUTIDA (P. putida) for ISOPRENOL production as a PRECURSOR FOR SUSTAINABLE AVIATION FUEL. An open-access paper on their work is published in the journal Metabolic Engineering.

Isoprenol is a chemical involved in the production of a jet biofuel blendstock called 1,4-DIMETHYLCYCLOOCTANE (DMCO). Researchers have produced isoprenol in several microbial hosts. However, efforts to make sustainable aviation fuel would benefit if isoprenol could be made in microorganisms that use fermentable sugars from plant material as a source of carbon. P. putida could be such a microorganism, but it needs engineering to be an optimal choice.

The team used computational modeling to predict targets for gene editing and to optimize metabolism in P. putida to maximize the production of isoprenol. This approach allowed the researchers to select and prioritize gene editing targets and therefore to test a smaller number of engineered strains.

In addition, they applied known genetic edits to further improve isoprenol production and used proteomics to optimize the process.

The research achieved a 3.5 grams per liter isoprenol production titer, the highest reported for P. putida. The researchers concluded that their pathway optimization therefore resulted in a 10-fold improvement of isoprenol in P. putida. The researchers suggest additional improvements must be made to improve isoprenol yields for industrial applications.

Commercial-scale production of isoprenol and DMCO at commercial scale still requires additional improvements such as the inclusion of CRISPR gene editing and other bioprocess technologies.

The research was funded by the Joint BioEnergy Institute supported by the Department of Energy Office of Science, Biological and Environmental Research Program.

Resources

- Deepanwita Banerjee, Ian S. Yunus, Xi Wang, Jinho Kim, Aparajitha Srinivasan, Russel Menchavez, Yan Chen, Jennifer W. Gin, Christopher J. Petzold, Hector Garcia Martin, Jon K. Magnuson, Paul D. Adams, Blake A. Simmons, Aindrila Mukhopadhyay, Joonhoon Kim, Taek Soon Lee (2024) “Genome-scale and pathway engineering for the sustainable aviation fuel precursor isoprenol production in Pseudomonas putida,” Metabolic Engineering, Volume 82, Pages 157-170 doi: 10.1016/j.ymben.2024.02.004

Posted on 10 May 2024 in Aviation & Aerospace, Biotech, Fuels, Market Background, Synthetic Biology |

++++++++++++++++++++++

Scaled demonstrator rises from the flames[2] to showcase distributed propulsion potential

By Dominic Perry8 May 2024

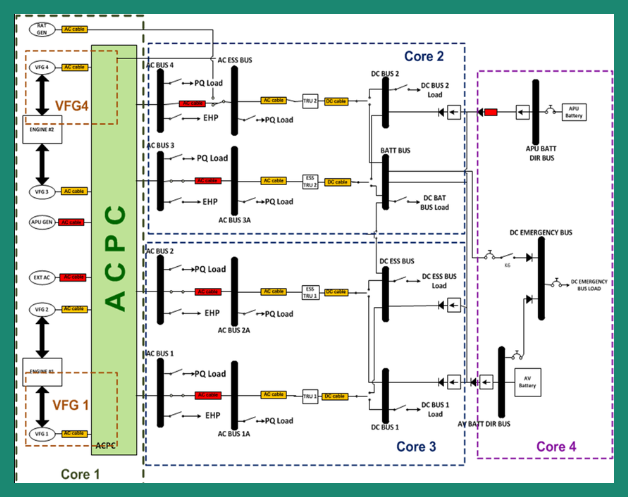

Dutch researchers have completed the first flight of a new scaled demonstrator designed to evaluate the potential for future passenger aircraft using a DISTRIBUTED ELECTRICAL PROPULSION (DEP) ARCHITECTURE.

Taking place at Taranto-Grottaglie airport in southern Italy, the 2 May sortie saw the demonstrator perform a flight of around 10min, including an approach just over the runway, before landing successfully.

Maiden sortie of 4m-wingspan demonstrator took place in southern Italy

“Subsequent flights will aim to qualify the aircraft for measurement flights, during which dynamic manoeuvres will be executed,” says the project lead, Royal NLR, the Netherlands Aerospace Centre.

Future flights will analyse the DEP architecture’s performance, including analysis of different control algorithms and the potential to control the aircraft through differential thrust on the propulsors.

With a 4m (13ft) wingspan and a take-off mass of 167kg (368lb), the demonstrator is equipped with six electric motors – a pair inboard on each wing and one on either wing-tip – and should be able to cruise at 100kt (185km/h).

Such a configuration should deliver a 20% REDUCTION IN ENERGY consumption for a full-scale aircraft, believes the Royal NLR.

Part funded by the EU’s Clean Sky 2 programme, the project also involves Airbus, the French and Italian aerospace research agencies ONERA and CIRA, and TU Delft and Orange Aerospace.

It builds on windtunnel and flight tests in 2022 of a 1:8.5-scale flight demonstrator powered by a pair of jet engines. Designed to validate the overall methodology, data collected by the flight-test instrumentation was compared against results from a full-scale aircraft.

That aircraft was subsequently converted into a DEP testbed – gaining a battery pack and propellers – but was destroyed after it caught fire in May last year during ground tests at Royal NLR’s facility in Amsterdam.

A redesign of the platform resulted in the latest iteration. “Despite the setback, the project partners remained resolute and viewed the incident as a valuable learning experience,” says Royal NLR.

Dominic Perry is deputy editor of Flight International but also contributes extensively to flightglobal.com. Although specialising in the coverage of the helicopter industry, he has written on most topics in aerospace – be they commercial, defence or business aviation. In addition, there has been an increasing focus on the decarbonisation of the industry and zero-emission flight initiatives.

+++++++++++++++++++++++++

[1] Electric propulsion replaces conventional jet propulsors with electric fans powered by electric generators rotated by an engine, a combination of generators and energy storage, or just energy storage. An appealing idea is to distribute the electric fans along the aircraft wings or tails to improve aerodynamics, boost energy efficiency, and reduce carbon emissions and acoustic noise. Focusing on distributed electric propulsion (DEP) systems, this article reviews the state-of-the-art advancements in aircraft electrification.

[2] Earlier crash of a demonstrator aircraft.