Underneath the surface of EMAS- public servants made it happen

Below is an article describing the installation of an innovative safety addition to a runway at Philadelphia International Airport. The author lists the benefits of this installation, the federal standards and funding facilitating this added margin of safety, the work of the airport staff, the contributions of the local contractors, the history of overrun runways and how many other airports have this same arresting materials.

The FAA Administrator recites those who made this happen. He did not mention (i) the years of research and development which his William J. Hughes Technical Center performed to design the engineering parameters (ii) the joint industry/FAA work to assure that once in place the system will arrest aircraft after over running a runway even after weather and exposure and (iii) the promotion of this safety enhancement after it was approved.

It is not de rigueur these days inside the Beltway to give much credit to the career professionals who run the FAA and other executive branch endeavors. In fact, a Pulitzer award winning author has taken on the task of providing examples of the public servants who have met JFK’s call to serve America. The book, Who Is Government, by Michael Lewis, might well have included the back story not mentioned at the PHL ceremonies.

Here is a short precis of those career employees’ dedication to safety, described in detail in this document:

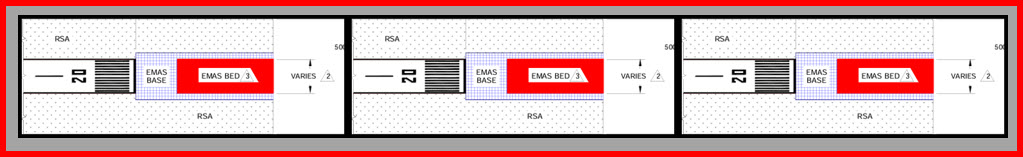

- In 1986, the FAA launched a research program to develop an engineered solution for airports with inadequate real estate for standard runway safety areas (RSAs.

- The initial goal of the research program was to establish the feasibility of placing soft, crushable materials in the RSA to safely stop aircraft that are not able to stop on the runway.

- One of these materials was phenolic foam, which is a rigid foam board insulation product typically used in roof systems. Soft-ground arresting systems (SGASs) relied on the principle that the aircraft tires will deform or crush the soft material, and the resultant drag forces will safely and predictably decelerate the aircraft.

- From 1986 through 1993, the FAA conducted extensive research and testing on SGASs. FAA report DOT/FAA/CT-93/80 details the research conducted during this time.

- A mathematical model representing the tire/phenolic foam interface can accurately predict landing gear loads, deceleration, and speed decay of aircraft during simulated overruns.

- A Boeing 727 (B-727) aircraft traveling up to 60 kt can be safely stopped within a bed of phenolic foam in less than 1000 ft.

- Aircraft rescue and firefighting (ARFF) equipment and personnel were able to maneuver without difficulty on the phenolic foam bed following an aircraft arrestment. By 1993, the FAA had established the feasibility of SGASs.

- There remained a challenge with the second part of NTSB Safety Recommendation A-84-37 that states, “…promulgate a design standard, if the systems are found to be practical” [3]. The phenolic foam proved adequate for testing purposes but was deemed impractical for operational use.

- COLLABORATIVE PARTNERSHIPS. In 1994, the FAA resumed their SGAS research program with the goals of (1) developing a more effective system, (2) demonstrating a prototype, and (3) creating a standard that would provide industry with guidelines for the design, installation, and maintenance of an SGAS. These three goals aligned with the respective capabilities and needs of ESCO, the PANY&NJ, and the FAA. In 1994, ESCO was a world leader in military aircraft arresting systems, and the company was exploring an expansion into the civil aircraft arresting market.

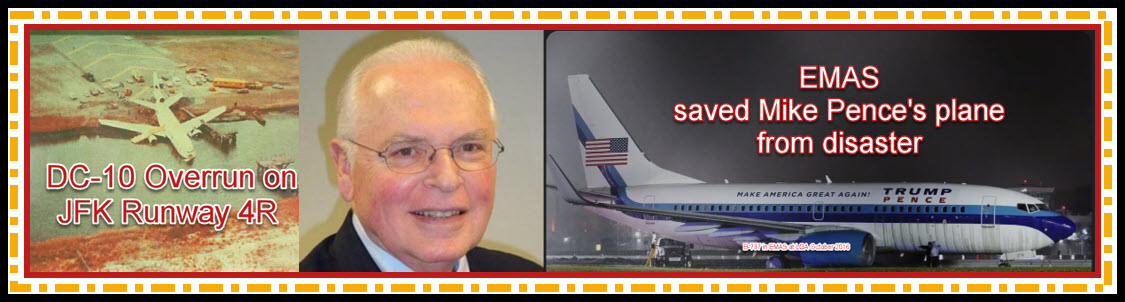

Projects like EMAS must have a GOD FATHER to assure that momentum is sustained throughout an organization like the Tech Center, reminds the user organization (here FAA Airport Safety at headquarters) to add to the project’s outcome and apply pressure at the highest levels of the value of the budgetary support for this development. That figure here, appropriately an Italian American engineer, was JOSEPH DEL BALZO [1]served as Director of the FAA William J. Hughes Technical Center and later as Acting Administrator of the FAA in 1993. These positions placed him at the center of aviation safety innovation during the formative years of EMAS.

His tenure coincided with the FAA’s increasing focus on mitigating runway overruns—especially at airports with limited Runway Safety Areas (RSAs). His leadership helped prioritize funding and institutional backing for EMAS feasibility studies and prototype testing. His interest in this safety advance would be confirmed by he other participants, FAA technical staff, the Airports Safety team, the aircraft users whose plane/passengers are protected by EMAS, the airports that have or are about to add this installation and the companies that are now reducing risk with this innovation. Joe helped the FAA to write the Advisory Circular that explained to airports and contractors how to implement this plus; AC drafting all too often delays the realization of the new safety approach; Joe made sure that this one was expeditious. He even had a hand in the EMAS construction at JFK just n time for a Saab 340 the arresting system to stop it from hitting the water.

PHL Completes EMAS on Runway 8-26

Written By: Shelby Holmes

On June 12, the Department of Aviation completed the city’s first Engineered Material Arresting System (EMAS) on Runway 8-26 at Philadelphia International Airport (PHL). EMAS is a safety feature installed at the end of runways to stop overrunning aircraft. The project falls under the Airports Capital Development Program and aims to bring the Runway Safety Area (RSA) to compliance with Federal Aviation Administration (FAA) standards.

In the 1990s, the FAA began to conduct research alongside the University of Dayton, the Port Authority of New York and New Jersey and the Engineered Arresting Systems Corporation (Runway Safe Inc., of Logan Township, New Jersey), on how to improve airport safety when the full RSA cannot be obtained. Six years later the first EMAS was built at John F. Kennedy (JFK) International Airport. Today there are 118 EMAS SYSTEMS INSTALLED AT OVER 69 AIRPORTS IN THE UNITED STATES.

EMAS is designed to stop an overrunning aircraft traveling at up to 80 miles per hour by using crushable material installed within the overrun area. When an aircraft enters the EMAS, its landing gear compresses the material, which is installed approximately three inches below grade level. This process decelerates and safely stops the aircraft.

“At the FAA, safety is always our top priority,” said FAA Administrator Bryan Bedford. “To date, EMAS has safely stopped more than 20 overrunning aircraft carrying over 430 crew and passengers. It is one more tool that helps us keep travelers, crews and aircraft safe – and we’re glad to see it in place here. Thanks again to the Philadelphia International Airport team, our industry partners, and everyone else who helped make this project a reality.”

Runway 8-26 is located on the east side of PHL and operates as a commuter runway for general aviation. The 5,000 ft.- by-150 ft. runway was designed initially to separate commuter traffic activity from larger aircraft activity. Runway 26 provides precision instrument approach in low-visibility conditions, equipped with a Category 1 (CAT I) instrument landing system (ILS), high-intensity runway lights (HIRL), centerline lighting, and Medium Intensity Approach Lighting System with Runway Alignment Indicator Lights (MALSR). The EMAS is located beyond the end of Runway 26 and centered on the extended runway centerline. It is setback from the runway end at a distance of 389 ft to avoid damage due to jet blast and undershoots. The 211 ft EMAS bed consists of 2,184 crushable cellular concrete blocks constructed on a paved base. The installation was designed to support critical aircraft as well as withstand all local weather, temperature, and soil conditions.

Construction for the EMAS began in September 2024 and was completed ahead of schedule in partnership with J.J. Anderson. THE PROJECT ALSO RECEIVED AN $8,547,648 AIRPORT INFRASTRUCTURE GRANT FROM THE FAA.

The scope of work included:

- Demolishing Vehicle Service Road and electrical (cables, junction boxes, ductbanks)

- Dismantling and restoring MALSR

- Installing stormwater management measures

- Installing proposed utilities

- Grading project site

- Monitoring settlement of proposed fill

- Constructing proposed pavement

- Installing EMAS bed

- Creating pavement markings and grooving

- Restoring site

“The recent placement of the EMAS bed on the runway is a planned safety enhancement. It’s a proven system used at airports around the country to enhance safety for passengers and crews,” said Airport Engineering Assistant Manager Lee Sutanto. This project reflects our ongoing commitment to meeting FAA safety standards and best practices.”

Congratulations to the entire project team, including the Department of Aviation’s Engineering team, its consultants and contractors:

- Design teams: ADCI, RunwaySafe, AtkinsRealis, RS&H, Hunt Engineering, C&S, Urban Engineers, AGES

- Construction Management: JMT

- General Contractor teams: James J. Anderson Construction Company (JJA), Delta Line Construction, RunwaySafe, BillyBoy Contracting, Vann Organization, SJA Construction, RAM-T, MPatterson Services, Flynn, AKM, Compliance Plus

[1] Mr. DelBalzo is not only the founder of the firm sponsoring this blog, but his example of what public servants are expected to do gave me direction while I was at the FAA.