Timely Formation of Aviation Supply Chain Integrity Coalition

February 29, 2024 a/k/a LEAP YEAR day

The Honorables Sumwalt and Procari convened a meeting of all the participants in the Aviation Supply Chain from the OEMs (powerplant, airframe, avionics) to intermediate Part 145 Repair Stations as well as intermediary Parts Suppliers plus FAA PMA/TSOA/STC holders and finally to the AIRLINES. Ateither end of this linkage, there is a regulatory requirement to examine the providers of outsourced materials—the OEMs and the air carriers must inspect these suppliers before beginning their purchases and during the DC process on intake.

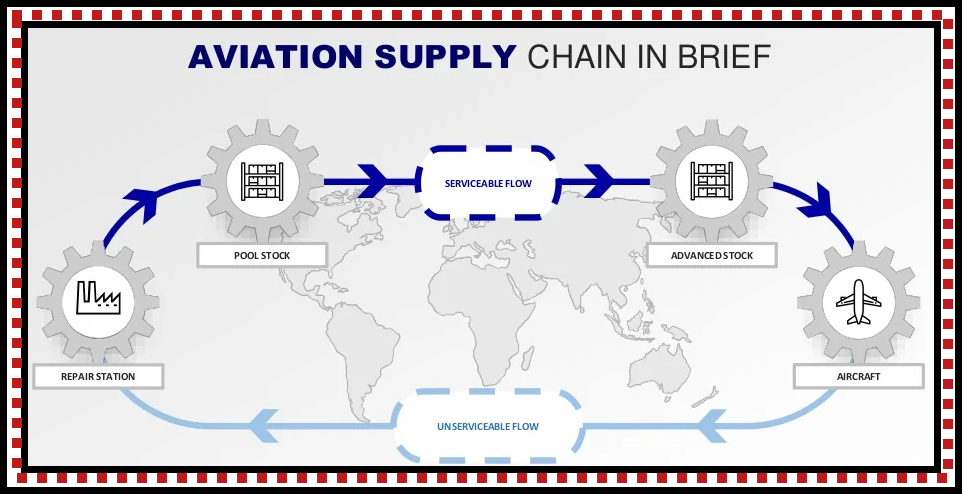

The Aviation Supply Chain both holds great risks from SUPs and other poor airworthiness integrity and tremendous potential for improving the flow of critical parts, assemblies, and systems. Like all logistics, post COVID. The passage of the elements of these aeronautical products has been subject to irregularities.T he September 21, 2023, the Federal Aviation Administration issued an Unapproved Parts Notification (UPN) over a bushing part supplied by AOG Technics without FAA production approval. That action catalyzed the formation of the AVIATION SUPPLY CHAIN INTEGRITY COALITION (ASCIC).

The AOGscam added a pernicious aspect of this system problem—the potential use of AI and photoshopping to create counterfeit documentation. ASCIC can create a closed loop of participants in a Supply Chain that can maintain the integrity. Industry standards for documents (holographic mark?) issued by all members would be one possible response.

A CLOSED LOOP, BLOCK CHAIN, STRUCTURE should minimize the introduction of unairworthy elements into the flow of parts.

ASCIC could collaboratively establish standards for airworthiness. Experts can refine specifications as to types of parts. The Coalition could employ Subject Matter Experts who are responsible for being on top of UPNs and researching new potential problems. A centralized resource might serve as a common place to see if a part is just the product of the precision of laser and 3D reproduction of parts. This Coalition Criterion would be the basic imprimatur attached to the flow between the members.

BLOCKCHAIN TECHNOLOGY has been introduced into the aerospace sector. Some existing systems (i.e. Honeywell’s GoDirect Trade online aircraft parts marketplace) have already transformed the documentation. Instead of relying on databases, spreadsheets, or paper logs, blockchain creates an immutable digital record of scheduled and unscheduled maintenance activities for each aircraft. In summary, blockchain is streamlining record-keeping, enhancing collaboration, ensuring trust in the used parts market, and providing comprehensive visibility into aircraft components.

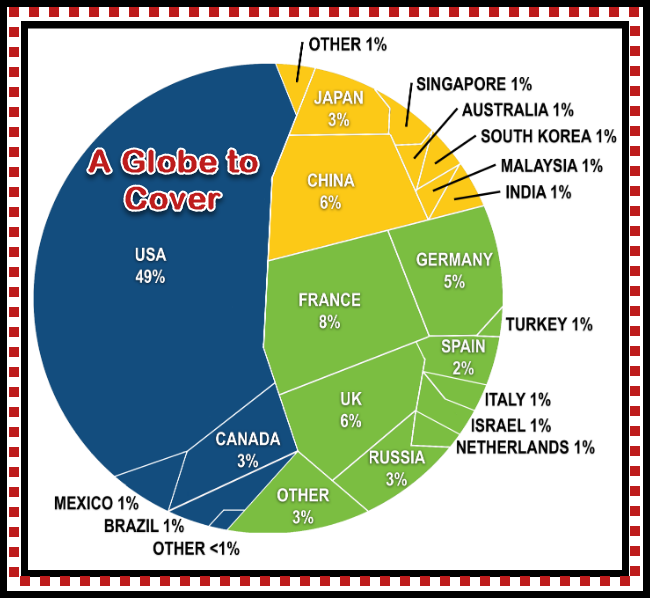

ASCIC holds an opportunity to reduce significantly the many risks inherent in this global aerospace supply chain.

Aerospace Industry Leaders Form Coalition to Strengthen Aviation Supply Chain Integrity

Feb. 22, 2024

Members seek to prevent introduction of unapproved aviation parts into the supply chain

Leaders from across the aerospace industry in the United States and Europe on Feb. 22 announced the creation of a coalition to help prevent unauthorized parts from entering the aviation supply chain and to strengthen the supply chain’s overall integrity.

Founding members of the AVIATION SUPPLY CHAIN INTEGRITY COALITION include senior representatives from Airbus, American Airlines, Boeing, Delta Air Lines, GE Aerospace, Safran, StandardAero and United Airlines. Former NTSB Chairman ROBERT SUMWALT and former U.S. Transportation Deputy Secretary JOHN D. PORCARI will serve as coalition co-chairs.

The coalition’s efforts build on CFM International* and its parent companies’, GE Aerospace and Safran Aircraft Engines, prompt and decisive actions last year when AOG Technics sold engine parts with forged documents. While an extensive review found that less than one percent of CFM engines were affected and most parts involved were non-serialized items like bolts, washers, and bushings, the coalition will take a broader look at preventing future similar actions.

“We were able to stop a rogue actor and quarantine the parts last year thanks to swift action from the aviation industry, but more is needed to stop anyone who tries to take a shortcut in the future,” said co-chair Robert Sumwalt.

“Through this coalition, we will work to find lasting solutions that the industry can adopt to improve the overall integrity of the aviation supply chain,” said co-chair John D. Porcari.

The coalition began its work this month, launching A 90-DAY REVIEW TO DETERMINE OPPORTUNITIES TO STRENGTHEN EXISTING SUPPLY CHAIN OPERATIONS. This work will form the basis of a comprehensive report with recommendations to ensure compliance with safety standards and prevent the introduction of unapproved aviation parts into the supply chain. The coalition’s approach spans the industry, drawing on expertise from manufacturers and airlines to maintenance, repair and overhaul stations, among others. The report is expected later this year.

“One bad actor is one too many in an industry so focused on quality and safety. We look forward to collaborating with leaders across the aviation industry to find meaningful solutions we can implement quickly to prevent this from happening again,” said GE Aerospace Chief Transformation Officer Phil Wickler, one of the coalition’s members.

About Robert L. Sumwalt — Sumwalt is the executive director for Embry Riddle’s Boeing Center for Aviation and Aerospace Safety. He previously served as the chairman of the National Transportation Safety Board after being on the board for many years and had support of presidents from both parties for his nominations.

Before joining the NTSB, Sumwalt was an airline pilot for 24 years. He accumulated more than 14,000 flight hours, and he has co-authored books on aircraft accidents and Safety Management Systems. He also has published more than 100 articles on transportation safety and aircraft accident investigation. He earned a Master of Aeronautical Science (with Distinction) from Embry-Riddle Aeronautical University.

About John D. Porcari — Porcari is a nationally recognized public and private sector infrastructure leader. He most recently served as the Port and Supply Chain Envoy to the Biden-Harris Administration Supply Chain Disruptions Task Force to address supply and demand mismatches that emerged during the pandemic.

As Deputy Secretary and Chief Operating Officer of the U.S. Transportation Department in the Obama-Biden administration (2009-2014), Porcari was directly involved in FAA regulatory and operational issues and NextGen implementation. He also guided the department during the grounding of the Boeing 787, allowing personal electronics to remain on but in airplane mode and several other aviation safety incidents.

*CFM International is a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.