Advice on how to deal with DECEPTIVE PART documents

Aviation Daily (see below) has published its usually informative report about the work of the AVIATION SUPPLY CHAIN INTEGRITY COALITION, formed in response to a seminal aircraft parts fraud. The paramount lesson of the coalition’s work is the “IMPORTANCE OF EMPLOYEE KNOWLEDGE AND EXPERIENCE—something that no amount of technical advancement can offset completely.”

One of the prime reasons why in 1944 sovereign nations (52,now 193) reached a consensus to form the International Civil Aviation Organization was the CREATION OF SAFETY STANDARDS APPLIED TO ALL FLIGHT. Perhaps not contemplated then, comparable airworthiness criteria are the reasons why safety has achieved such a high level of performance.

Within the scope of this approach is the ability of airlines and other aircraft owners to acquire parts and equipment based on documentation that is recognized as RELIABLE, i.e. the form indicates that the article being conveyed is AIRWORTHY. The catalyst for forming the Coalition, extensive use of doctored forms, diminished or nearly destroyed that presumption. The incident showed the consequences of this breach—thousands of hours of CA/QC inspectors laboriously examining, with justifiable suspicion, records and researching their alleged provenance. Whatever was saved by buying at a discount was lost within minutes of these audits!!!

The ASCIC #1 recommendation is to avoid such consequences by educating the part intake team to detect forged documents. The form’s authenticity is not discernable by examining the paper only ; technology has made it almost impossible to identify reproduction.{Boeing is working to created electronic records that are less susceptible to being altered.}

Your team should, soon, be equipped with the ability to find the glitches in the product’s history that are tells of bogus parts. Examples of such detective work should include these examples:

- Passing of a part from one inventory to another that would not have use for it (i.e. an all-Boeing company acquiring an Airbus article). The auditor would have to have detailed knowledge of the airline fleets.

- Part of a part’s history is repair with an MRO. Not all Part 145s are created equally and not all Civil Aviation Authorities are not known for rigorous surveillance of those companies. A list of competent MROs and CAAs is not easily compiled.

- Brokers run a gamut –

- some are known for incredible technical engineering competence and their airworthiness judgment merits trust. Some do not have such a reputation.

- Part brokers tend to specialize, for example, they only buy and sell avionics. A FAA 8130-3, issued by a reputable Part 145, for a hydraulic actuator sold by from firm should raise flags.

- Serialized parts generally are traceable, but even then a forger knows to engrave the right numbers on them. Not enough, additional research of when the numbers were issued and where the source was.

- Distressed airlines and regions are prime sources of bogus parts. The sellers know to move their suspect inventory through multiple intermediaries to obfuscate their illegitimacy. Some CAAs have issued standards for companies within their jurisdiction that do not meet global requirements. Knowledge of these regulatory ruses is critical to preserving the integrity of our inventory.

This short list should highlight that there are no universally applicable clues—what to look for when assessing turbine vanes is likely to have little relevance to an audit of landing gear assemblies. The education recommended by the ASCIC should be focused on the products that you buy or sell. The teacher for these classes should arrive with substantial insights into documentation, known SUPs and the sector in which you participate.

Memo

Industry’s Response To That Big Parts

Fraud Scandal? It’s Just Beginning

SEAN BRODERICK, sean.broderick@aviationweek.com

This fall, the AVIATION SUPPLY CHAIN INTEGRITY COALITION (ASCIC) is expected to provide a progress report on how industry is responding to what the group saw as an URGENT NEED to improve parts tracking.

Formed in the wake of 2023‘s AOG Technics parts documentation fraud scandal, ASCIC spent the better part of a year studying the commercial supply chain and considering ways to make it more secure. It delivered a report and 13 recommendations in October 2024 and pledged to do more than simply advocate to help its world view become reality.

As its upcoming update will demonstrate, the group is walking the walk.

In July, it organized the first of several planned webinars linked to its recommendations. The inaugural topic addressed arguably the lowest hanging fruit in industry’s push to stop document fraud: training for front-line employees.

StandardAero VP of Product Assurance and Quality BRENT OSTERMANN shared the framework of his company’s “Check for Acceptance” training. The course is mandatory for anyone who receives parts, including 500 clerks and 350 quality inspectors at 50 locations.

Such training is commonplace at companies that buy or sell aircraft parts. But smaller organizations may not be as comprehensive as StandardAero’s four-day program. By sharing it, ASCIC—which counts StandardAero as one of eight founding members—hopes to prompt action at companies seeking better processes.

StandardAero’s course and others like it are not simply exercises in regulatory box-checking. The AOG Technics scandal was exposed by a technician’s suspicion that a part did not match accompanying paperwork that claimed it was new. The paperwork was falsified—part of a years-long AOG Technics scheme that saw thousands of parts sold with similarly faked records.

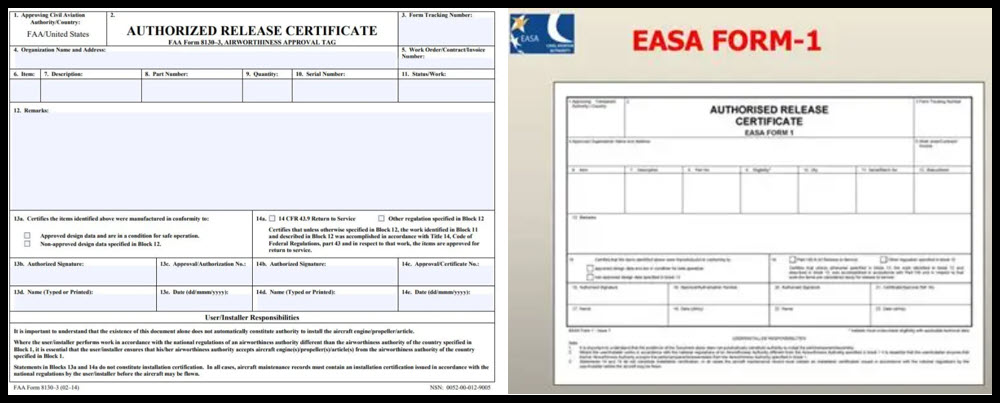

The fraud wasn’t too advanced. Somebody altered scans of AUTHORIZED RELEASE CERTIFICATES (ARCs)— s and European Union Aviation Safety Agency Form 1s. Perhaps added “new” to the correct block to make the component appear as if it came directly from its manufacturer and has never flown. Perhaps changed a work order or part number.

Ostermann used the webinar to share a similar example involving StandardAero. A French supplier purchased a used propeller from a UK vendor. It came with an ARC seemingly prepared by StandardAero. A quality manager at the French company knew StandardAero serviced propellers but was not sure about this particular model.

A phone call to StandardAero confirmed the manager’s suspicions: the propeller was not on StandardAero’s capabilities list. Somebody took a scan of an authentic ARC for a fan blade and doctored it to go with the propeller.

“With a little bit of awareness and a little bit of education, we were able to avoid this one,” Ostermann said.

Such examples hammer home the IMPORTANCE OF EMPLOYEE KNOWLEDGE AND EXPERIENCE—something that no amount of technical advancement can offset completely. But better processes will help—and ASCIC, which has added a few members that will officially be welcomed as part of its one-year update, is deeply involved there, too.

Coalition member Boeing is working with a major U.S. airline and data exchange specialist on electronic 8130-3s. These aren’t run-of-the-mill scans of the current form, but rather data containers that permit adding information as a part moves through its lifecycle.

Instead of a note saying details on a repair are on file at some repair station, the electronic 81 30-3 will have all the data avail- able on the work—and any other repairs, sales, or other changes to its status, too.

The AOG Technics scandal didn’t introduce aviation to parts fraud, nor can it be credited for giving birth to records digitization efforts. But the scheme’s sheer scale, touching thousands of parts and more than 100 engines, is changing the narrative around both the issue and potential solutions.

ASCIC’s role is straightforward: Keep it all in the spotlight until complete sets of digitized parts records securely in the cloud are as commonplace as boarding passes on smartphones. •